Pick a subject in the menu to the right and click the question to reveal its answer. If you cannot find the answer to your question within this FAQ, feel free to contact us via technical support, or give us a call at 504.529.1413.

Hardware

What are display stats?

These display stats can be added to VAV controllers or to Professional line controllers (using a SI-S3 Stat Interface board). Only one S3 can be added to a VAV, but it does not require an interface board. You must follow different methods to add a S3 to the 2 different controller types.

Adding a Display Stat to a VAV

Once you have wired the Siebe S3 to Analog Input 3 of the VAV controller, you are ready to program it in Editor Mode of CBAS. First program the VAV controller, then follow the instructions below.

- From the main menu, click on Database, then click Add a Controller.

- In the first window, give the controller a descriptive name and click Next.

- Choose Siebe on the left side of the next window and S3 on the right side.

- Click Next and choose the VAV controller that will be hosting the display stat.

- Click Next and click Finish in the next window, which lists the Channel and the address on the channel. There is only one address available on the Siebe Channel hosted by a VAV controller.

- You can now find the VAV controller in Hardware view. Click on the controller and click Channels.

- Click on Siebe Channel and click Controllers. You will see the Display Stat listed.

- Click on the Display Stat and click Points. You will see a list of points with “Add A Point” next to each. These points are standard points, but they need to be added in order for them to show up in Text View.

- Click Add A Point next to the points you want to use.

- Give the point a descriptive name and select the one available configuration. Click Add Point Now.

The functions of the points are pre-determined and most are obvious. Here’s a description of some of the less obvious ones:

- Mode: There are 5 modes, which determine what is seen in the display on the Wall Stat itself. The modes are:

- Temp: Stat display shows the Space Temp

- SPTemp: Display shows Setpoint when in occupied status, shows Space Temp when in unoccupied status.

- Setpnt: Shows Setpoint all the time

- Altern: Display shows Alternate Display Number, which can be set to anything

- RH: Display shows Relative Humidity if programmed (only thru VAV)

- Alternate Display Number: Put in the number you want to be displayed when in Altern Mode.

- Unoccupied/Occupied Enable: When enabled, this allows you to change Occupied/Unoccupied mode from the button on the Display Stat.

If you need to program many identical VAV controllers with S3 Display Stats, you can use a template. Program the first VAV with the Siebe channel, display stat, and it’s points. Click on the VAV controller and click Save Controller Database as Template. When programming the subsequent controllers, choose to create the controller from template, instead of a blank database.

Adding a Display Stat to a Professional Line Controller

In order to program a Wall Stat, you must first program the controller that it is wired to. Let’s assume we have an 8X controller programmed on a TCP/IP channel already.

- In Editor Mode, go to Hardware View, TCP/IP Controllers channel, Controllers button, and click on the controller that is to be used as the host channel for the Display Stat(s).

- Click on Channels, and click Add a Channel next to RS-485 Host.

- Enter a name for the channel and click Select Configuration.

- Choose Opto-22 on Controller and click Add Channel Now. This channel will not show up in the channel list in Hardware View. You will only be able to access it through Channels on the controller.

- To program the Wall Stat on the Channel you created, click on the channel you just created and click Controllers. Each line corresponds to an address.

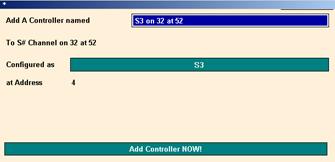

- Click on the address you want to add a S3 to and you will see the following pop-up.

- Give it a descriptive name.

- Click “Select Configuration” and choose S3.

- Click “Add Controller NOW!”

- To add points to the S3, click on it, then Points.

- Click on Add A Point next to the point you want to program and give it a name that includes the name of the Wall Stat.

The names and functions of the points are the same as those added through a VAV.

It is a good idea to erase any database that might be on the Wall Stat host controller when opening the database in Real Mode after adding a Wall Stat to the database. To do that, click on the Wall Stat Host controller and click Erase Database. The controller will automatically download the new database.

Setting the Address on the Stat Interface Board

There are toggle switches numbered 1 thru 8, which relate to the values of a binary Byte. Flip enough toggle switches to equal the number of the address. The values are as follows:

- 1 = 128

- 2 = 64

- 3 = 32

- 4 = 16

- 5 = 8

- 6 = 4

- 7 = 2

- 8 = 1

For example, a controller with address 10 would have switch 5 and 7 in the ON position. 8 + 2 = 10

Address 97 would have switches 2, 3, and 8 in the ON position. 64 + 32 + 1 = 97

Lights on the Interface Board:

- +5V: This light should be solid green when power is properly applied.

- RUN: Steady red blink when the board is running.

- STAT: Steady red blink when communication is established with the Display Stat (Stat will display also).

- RxD: Steady fast yellow blink when normal RS-485 communication is established.

- TxD: Occasional green blink when normal RS-485 communication is established.

Known Limitations:

There is a problem with mode. Mode has 5 states (temp, SP & temp, SP, Alt, %RH). The RH mode does not work with the new S3 Interface firmware. So you can’t get the S3 to display Humidity when going through an 8X. All display modes work when attached to a VAV.

When you change the range of the S3 Setpoint in CBAS, it will not download automatically to the Display Stat. It should download after commanding the Setpoint in CBAS. If it doesn’t, a download can be forced by cycling power to the Interface board.

As of version 1.5.22 of CBAS, the Humidity point was added to S3 Display Stats with humidity capability, but only for use with VAV controllers. Now, Humidity is functional on the Professional line of controllers, through the host or secondary channel using a Stat Interface board. The requirements for this are: upgrade firmware on the Stat Interface board (cin# AB90; possible firmware upgrade to board hosting S3 channel. (V8.8)

There are 2 ways of using the S3 with an interface board. One is to add it to an Opto-22 on Controller channel and the other is to put it on an Opto RS-485 over TCP/IP channel. Here’s the difference: When you add it to the Opto-22 channel, it becomes part of the database on the host controller. This is the preferred way, because the controller and the S3 stats are always talking, even if the head end computer is down. If you add the S3 to an Opto RS-485 over TCP/IP channel, the points on the S3 do not become part of the database on the host controller. The host controller only passes the information back and forth between the head end and the S3. It is not necessary to upgrade the firmware on the Stat Interface.

How do you delete a Database from a Controller?

There are four ways of deleting the database from a controller:

- From CBAS in Hardware View, locate and click the controller, then click Erase Database. CBAS must be in Real Mode with Normal communications to the controller. After rebooting, the controller will immediately download the database again.

- From the Handheld, go to the Main Menu.

- Hit 5 (not listed) then Enter

- Hit Select to Delete

- Follow instructions, cycle power to controller

- Connect using HyperTerminal (That’s another story)

- Type the command: ERASEDATABASE

- Using the Address Dials on an 8X, 16X, 32X, or 64X.

- Set Red Dial address to 999.

- Power up the board.

- Change Red Dial address to 990.

- Change Red Dial address to 900.

- Change Red Dial address to 000.

- At this point the controller would recognize this number sequence and erase the database.

- It will ONLY work if the Red Dial address is 999 after a power up.

Can paint fumes damage carbon dioxide sensors?

Gas sensors based on solid-state (Figaro®) sensors are another story entirely. Their sensing surfaces are designed to react chemically with volatile organic compounds, which are exactly what drying paint gives off. Thus, high levels of paint fumes can easily poison them. VOC sensors, lower-end carbon monoxide sensors, and other toxic or combustible gas sensors based on a solid-state element should be removed from the room prior to painting in order to protect them. Note that simply covering them with plastic won’t do the trick unless it’s airtight.

Reproduced with exclusive permission from Kele © copyright 2004

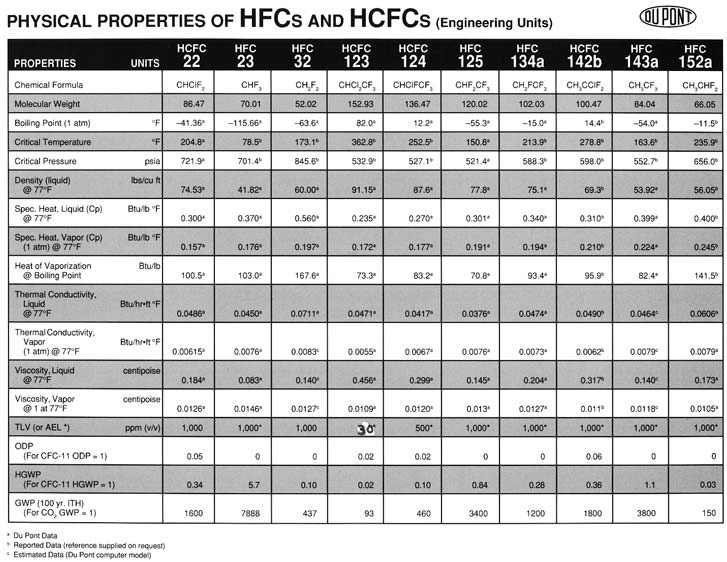

What are Physical Properties of HCFCs and HFCs?

There are so many thermistor manufacturers, how can I choose a high quality sensor?

About 50 years ago, Bell Telephone Laboratories started investigating various materials and processing procedures to determine how to make stable and reproducible thermistors. They were quite successful in their investigations and actually put thermistors into large scale telephone usage about 30 years ago. The units they developed were both highly stable and closely reproducible to standard specifications. It is only in the last 20 years, however, that thermistors have been generally available for large scale industrial use.

There are so many thermistor manufacturers, how can I choose a high quality sensor?

The element is the key. The PreCon Raw Thermistor Chip is made of metal oxides compressed and heat treated to a coherent nonporous mass. This treatment process is what gives the thermistor its basic curve. The material is trimmed for the proper resistance at 25°C, leads are attached, and various chemical treatments are applied. The sensor is then encapsulated in a plastic cup to become a PreCon ST-R3. During the assembly process the sensors are 100% screened which assures the high interchangeability tolerance and long-term stability for which PreCon Sensors are known. PreCon utilizes a chemical compound more pliable than glass and yet more resistant to moisture than the epoxy used by other manufacturers. This process allows PreCon to warrant their sensors to be free from drift of more than 0.24°F for 5 years. The 8-foot leads attached to the sensor provide isolation from moisture which will destroy a thermistor.

My sensor reads accurately at room temperature but reads incorrectly at other temperatures. What is wrong?

Check the Characteristic Curve and Tolerance. The Characteristic Curve is the temperature/resistance curve that is established by the manufacturing process. This curve is the one most often used to describe the basic sensor characteristic. It does not describe the performance of the sensor. A major manufacturer of high accuracy thermistors catalogs four different sensors with the same characteristic curve. Each sensor becomes progressively more expensive as the sensor performance improves. To even be considered as an equal, a competing thermistor must have an identical curve. Any deviations in the curve indicate a questionable material mix and manufacturing process.

Tolerance is the ability of the thermistor to adhere to its characteristic curve. It is tolerance that begins to separate high quality thermistors from general purpose sensors. Good tolerance characteristics of a thermistor can be obtained in several ways. PreCon obtains tight tolerance by excellence in the manufacturing process. If the manufacturing process is correct, then the thermistor tolerance will be good. Some manufacturers use a selection process to obtain sensors that will meet predetermined tolerance specifications. This method is necessary when the manufacturing quality control is poor or the manufacturing techniques are not available for producing high quality sensors. In any case, sensors obtained by the selection method are not likely to maintain their tolerance over time or through temperature cycling which is characteristic of HVAC applications. PreCon warrants its tolerance over a period of 5 years.

How can I be sure I am getting a stable sensor that will not drift with time?

Stability is perhaps the most important, and yet the most elusive, of the key words which are used to determine quality. Stability is the term used to describe the characteristic drift that some thermistors display. Thermistors become more stable with time, with the most change in tolerance occurring in the first 6 months following manufacture. Stability is a function of the manufacturing process. Although the process is difficult and expensive, a high quality manufacturing process will yield pre-aged, highly stable thermistors. Since it is difficult to test a thermistor for stability except under laboratory conditions, the sensor manufacturer (assembler) should be willing to guarantee stability of the sensor they are selling. PreCon thermistors are inherently stable at 0.027°C a year. A competing thermistor cannot be considered an equal unless the manufacturer will offer the same guarantee.

Other companies sell “Bare Bead” thermistors mounted in space wall mount enclosures. Why doesn’t Kele?

Kele sells PreCon Thermistor Sensors. Simply stated, PreCon Sensors are designed to interface with automation systems more accurately than bare bead sensors. Most thermistor-based automation systems in use today will read room temperatures 1°F higher than the actual temperature if a bare bead sensor in a ventilated plastic enclosure is used to measure the space temperature. Heat is generated in all resistance temperature measurement devices as a result of current flow in the measurement circuit. PreCon Raw Sensors will dissipate the heat developed in the measurement circuit almost three times better (2.7 mW/°C) than a bare bead (1 mW/°C) sensor.

What is a heat dissipation constant?

Heat Dissipation Constant is the power in milliwatts required to raise a thermistor one degree centigrade above the surrounding temperature. Even if the zero power resistance/temperature curve claimed by the manufacturer is close enough to the PreCon Type III curve, so as not to cause readily apparent problems, other factors can cause significant and troublesome deviations from the actual performance of PreCon Type III Sensors. Wire size, type, and method of connection to the chip itself critically affect the ability of the sensor to dissipate the heat generated in it by measuring the flow of current through it. This is called “self-heating” and actually causes the complete sensor assembly to give readings that differ from the characteristic temperature curve. The wire PreCon uses is designed to limit the effects of self-heating, reverse temperature transmission, and moisture migration. The encapsulation material used to coat the thermistor provides a low mass and high conductivity for good heat transfer characteristics. The PreCon ST-R3 Raw Sensor has a Dissipation Constant in still air at 25°C (77°F) of 2.7 mW/°C. Most “similar” bead sensors on the market will self-heat at almost 3 times the rate of a PreCon ST-R3 Type III Sensor. A “similar” raw bead thermistor sensor may read correctly with an ohmmeter but exhibit a temperature indication error of one degree Fahrenheit when applied to a computer input. An equal raw bead sensor must possess the same Dissipation Constant to read as accurately as a PreCon Type III Sensor under the same conditions.

How to determine your sensor’s heating error:

- With the sensor connected to the computer, measure and record the voltage drop across the sensor.(E)

- Record the temperature reading at the sensor at the time of the voltage reading.

- Using the thermistor temperature/resistance chart, record the sensor resistance at the temperature measured above.(R)

- Record the heat dissipation constant for your sensor. [Typical Bead Sensors (K) = 1 mW/°C]

- Calculate the power generated in your sensor: P = E2/ R

- Calculate the temperature reading error:

- Error = Power Generated (P) / Sensor Dissipation Constant (K)

- Example:

- Bead Sensor (Heat Dissipation Constant = 1 mW/°C) Voltage Measured = 2.5V

- Room Temperature = 25°C (77°F)

- Sensor Resistance at 25°C (77°F) =10,000 ohms

- Power generated = E2 / R = 2.52 / 10,000 = 0.625 milliwatts

- Heating error = P/K = 0.625 mW / 1 mW/°C = 0.625°C

In this example the bead sensor would read 0.625°C high or in °F, 1.8×0.625 = 1.13°F high.

Reproduced with exclusive permission from Kele © copyright 2004

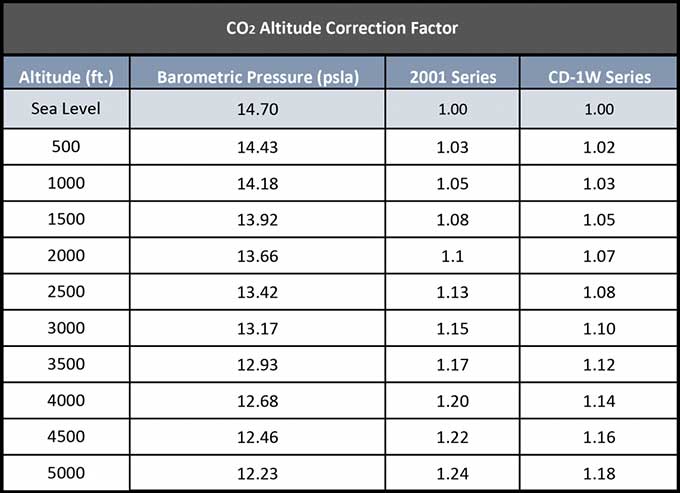

Did you know that the calibration of carbon dioxide sensors is affected by changes in altitude?

For example, assume a CO2 sensor (calibrated at sea level) operating at 3000 feet elevation reads 1000 ppm. Barometric pressure, and therefore air density, at this elevation is approximately 10% lower than the sensor’s calibrated conditions. This means the sensor reading will be 10% lower than the actual CO2 level. The CO2 level will be about 1100 ppm, not 1000 ppm as indicated by the sensor.

This correction is for the physics associated with the ideal gas laws. Some types of infrared CO2 sensors (such as the 2001 Series) utilize a pyroelectric element which is also affected by changes in pressure, so as the pressure decreases, corrections must also be made for the change in sensor performance. The chart on the opposite page shows the altitude correction factors for the carbon dioxide sensors offered by Kele .

To utilize this chart, simply multiply the sensor’s indicated CO2 level by the correction factor selected from the chart.

Reproduced with exclusive permission from Kele © copyright 2004