By GREG THOMAS Real estate writer July 24, 1998 Publication: Times-Picayune, The

Despite society’s increasing dependence on sophisticated electronics,

most of us still can’t program a VCR.

The same high-tech frustrations apply to managers of high-rise office buildings and sprawling commercial centers. Electronic systems have managed building functions since the 1960s, controlling when the lights go on, what temperature a room should be at a particular time or whether security or fire alarms should go off.

But building engineers are not computer technicians or electrical engineers, and while they may understand the intricacies of a heating and cooling system for a towering 1-million-square- foot building, they probably haven’t a clue how to service pre-programmed automation systems.

Marketing pure simplicity, the New Orleans company Computrols Inc. is racking up orders

designing, manufacturing, installing and servicing its own line of automation systems. The

company’s business hinges on the promise that building engineers can trust their own

employees to operate Computrols’ automation systems instead of paying for high-tech training

or relying on expensive service contracts with other system manufacturers.

While a handful of companies across the country, including Honeywell and Johnson Controls,

have dominated the building automation industry, Computrols has carved a niche utilizing a

single premise: Keep it simple, stupid.

Since a lucrative part of the automated building systems industry is service and repairs,

Computrols is gaining an edge by saving building owners time and money.

Computrols systems operate on English commands, not computer code. While other systems

may require lengthy, on-site computer board repair, Computrols systems are designed so that

one board is lifted out and replaced with a new one. The old board can be discarded or sent for

repairs.

To date, Computrols systems have been installed in high-profile properties such as the U.S.

Treasury and National Archives buildings in Washington, D.C., and the Statue of Liberty and

Ellis Island National Monument in New York Harbor.

The futuristic Enron building, ranked the top building in 1997 by the Building Owners and

Managers Association, and the sprawling Conoco Corporate headquarters, both in Houston,

have installed Computrols building automation systems. Local users represent most of the

Class A office towers in New Orleans’ skyline, from One Shell Square to the Pan-American

building.

In New York, at 919 Third Ave., a 1.4-million-square-foot 47-story building installed a new

Computrols system in 1996, replacing an outdated system installed when the building was

erected in 1970. Building manager Ralph Ardolina is a happy customer.

“Not to put the other manufacturers down – they all have good systems – but this one is more

user-friendly. Eventually, all of (the competition) will be doing what they’re doing,” Ardolina

said.

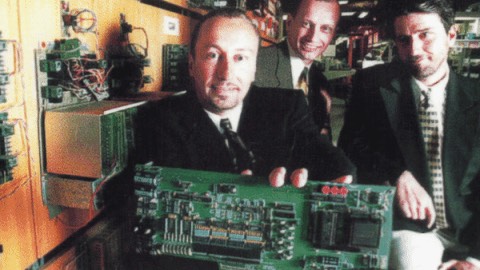

Computrols President Royden Lynch Jr., his brother Kevin and electrical engineer Mike

Donlon began Computrols in 1983 when they were in their early 20s. Today the partners run a

firm with four offices across the country and one in Moscow. Computrols is expected to gross

$5 million this year and has an annual payroll of more than $2 million for about 50 workers.

Royden and Kevin Lynch, who spent their formative years on a fishing camp in eastern New

Orleans, started Computrols to service existing building systems.

The Lynch brothers soon learned that servicing systems was cumbersome and expensive.

“Quite simply, the systems were designed by engineers for engineers. And it took technicians

with years of training in a specific product line to be able to work on a system,” Royden Lynch

said.

Lynch likes to show visitors a wall-to-wall bookshelf filled with manuals that technicians have

to learn in order to use his competitors’ systems.

And technicians can spend hours rewriting complicated computer codes for tasks as simple as

changing the trigger temperature for an exhaust fan to kick on

So the Lynch brothers, along with software expert Donlon, didn’t design a better mousetrap,

just an easier one.

“Put a bunch of engineers in a room and ask them to design something, and they’ll come up with something only engineers understand,” Lynch said.

To combat that, Lynch doesn’t approve new software or hardware unless someone with little

electronics background can understand how to operate it.

To date, Computrols has distributed its own systems, but Royden Lynch is seeking national

independent distributors.

A new software line utilizing Microsoft Windows software is on the way, but Computrols

programmers “haven’t gotten it simple enough yet.”

Computrols plans to invest $650,000 in new equipment that incorporates surface-mount

technology to build computer boards. While most boards take one of a dozen technicians about

45 minutes to complete, the new equipment will produce a board half the size in one minute,

Royden Lynch said.

Those technicians then will test boards rather than assemble them