In one of our recent articles, we discussed static pressure control and variable air volume (VAV) systems. We mentioned that by modulating the leaving air temp from an air handling unit (AHU) we can promote energy efficiency while also having an effect on static pressure. This time, we’ll look into how AHU supply temp sets the stage for efficient VAV operations.

Typically, VAVs are equipped with a means of reheating the supply air provided by the corresponding AHU. In many instances, the AHU’s leaving air or “supply” temp is maintained at 55 degrees F plus or minus a degree or two. One of the primary reasons for maintaining this air temperature is humidity control. Humidity can have a significant effect on everything from occupant comfort to how well the wallpaper sticks to the wall. The VAV’s will “reheat” this “supply” air to control space temp and control comfort levels in the space being served.

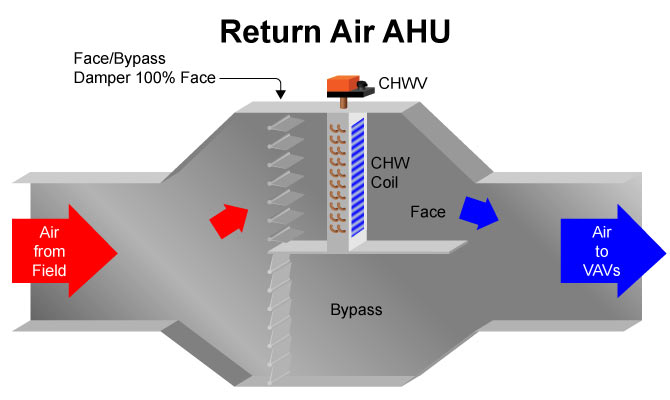

The incoming air to the AHU, be it pure space “return” air, fresh outside air or a combination of the two, passes through a coil or series of coils to remove moisture from the air to reduce humidity. In the South, the temperature of this air is usually warmer and moister than the desired supply temperature so we cool the air to accommodate the needs of the space.

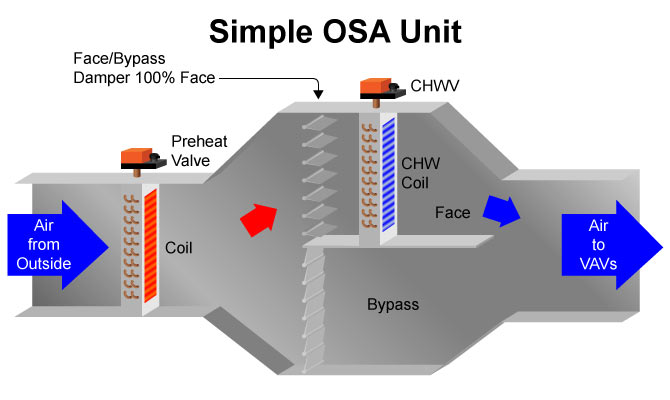

In the North, especially with 100% outside air units, cold outside air is the greater enemy so warming the air is usually the priority. In both cases though, altering the incoming AHU air temperature that will become the supply temperature reduces the humidity in the air. Monitoring humidity levels at the thermostat(s), and the supply and or return duct helps verify the effectiveness of the AHU in accomplishing this.

We’ve established that maintaining a proper supply air temp is important. However, this doesn’t necessarily mean we can’t modulate it to save some energy. After all, having 55 degree F air supplied to the space is going to force the VAV’s to reheat it to prevent cold calls. If we warm this AHU supply air up somewhat we can possibly prevent the reheats from being used as much and at the same time reduce the load on the AHU to condition the supply air temp. At the same time, if we warm the supply air too much, the entire space will warm up and possibly generate hot calls. The real trick in modulating the air temp to the VAV’s is to control the balance of comfort and humidity.

One very helpful method of accomplishing this balance is by effectively using “face/bypass” dampers. Face/ bypass dampers typically modulate to force air to pass through the “face” of an AHU’s cooling coil or to “bypass” around them. In some cases, there are both heating and cooling coils present and these dampers mix how much air passes through each coil. Either way, face/bypass dampers allow the supply air temp to modulate after being conditioned, i.e., dehumidified. Typically, the cooling coil is referred to as the “cold deck” and the heating coil, “hot deck”.

In the South, the typical variables we have in play are the supply duct temp, the cold deck and (if applicable), the hot deck temp. For the cold and hot deck set points, we can add a reset schedule to modulate the setpoints within a controlled range based on a separate temperature input. The input for this reset schedule can be outside air temp, return temp or even space temp deviation. In essence, the hotter the air is outside or coming back through the return air duct, the more we will want to “reset” the cold deck to a lower temperature. When these outside or return air temps are colder we can “reset” our cold deck to a higher temperature. The inverse would be true where the hot deck is concerned.

Again, the trick here is to modulate BUT to also maintain the supply air temp within the threshold of dehumidification needed by passing the air through the AHU’s coils. This is where face/bypass dampers come into play. Though the AHU must maintain the cold and hot decks within certain ranges for humidity control, (a topic unto itself), we can modulate the supply duct temp by using these dampers within a wider temperature range as it has already been conditioned.

As with the reset schedules for our cold/hot decks and the previous article’s mention of static pressure set points, a reset schedule can be used to modulate the supply duct temp via the VAV zone duct’s face/bypass dampers. A useful input for this can be the average of each VAV’s space temp deviation from their space temp setpoints. The hottest space temp can also be used to regulate the AHU’s cold deck reset schedule. Similarly, the coldest space temp can be used to reset the hot deck. The supply air temp after the dampers has a direct effect on how much or little heating is required for each VAV to produce in order to maintain space temp setpoint.

In conclusion, by warming the supply air temp to the VAV’s when the space they feed is satisfied, the first “stage” of heat becomes simply an absence of cooling. This can allow the VAVs to back off their CFM set points. This in turn slows down the variable frequency drive (VFD) for the fan motor of the AHU. This then slows down the airflow through the AHU’s coils thereby making it easier to raise or lower the temperature of the air passing through the coils. With the air temp easier to condition, the load is reduced on the system providing cooling and heating to the cold and hot decks. In the current age of automation options, these tasks become much easier to accomplish while at the same time adding somewhat more complex controlling methods. When it all comes together though, it’s quite a show. The end result is a system that can promote both comfort and efficiency while at the same time add to the energy conservation of the A/C systems when applied building-wide.