|

CBAS User Manual

Revised June 2020

©2020 Computrols, Inc.

All rights reserved. www.computrols.com

504.529.1413

2520 Belle Chasse Highway Gretna, Louisiana 70053

Chapter 2 » Getting Around CBAS

Chapter 3 » Programming Databases.

Chapter 4 » Programming Points

Point Program Screen Description.

Description of Software Points

Hotkeys for Use in CBAS Graphics Programming

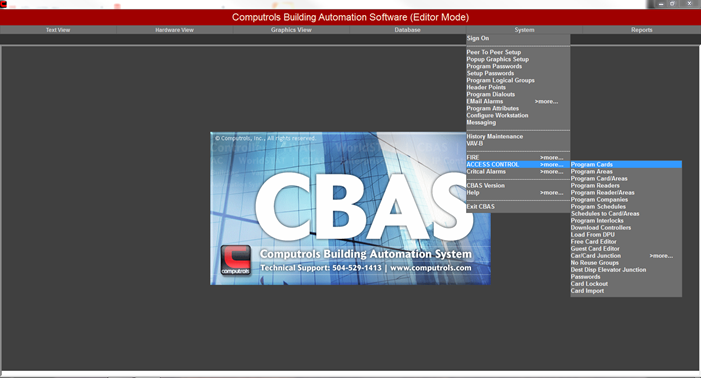

Chapter 6 » System/Database Menu.

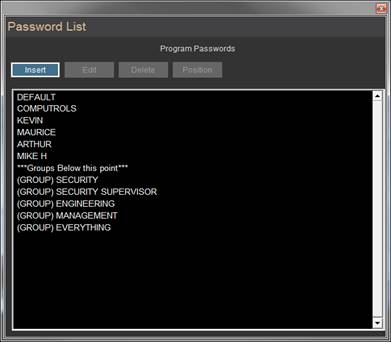

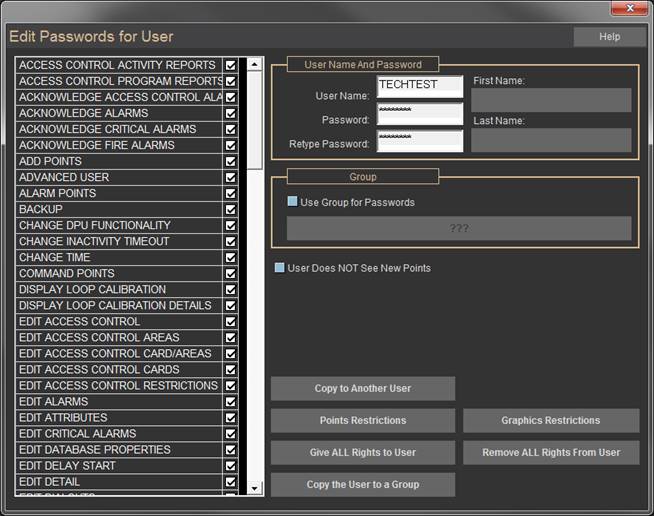

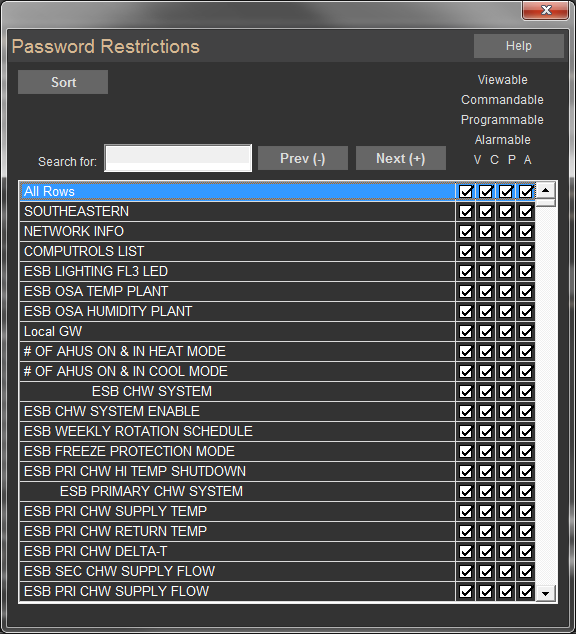

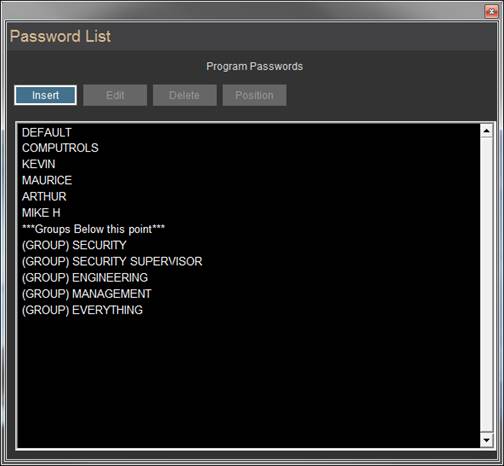

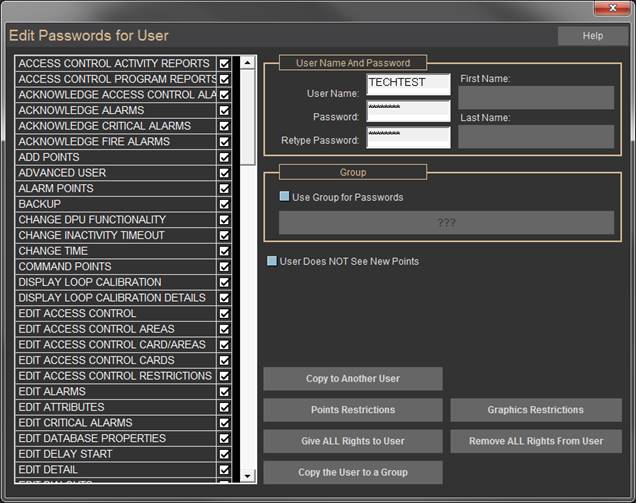

Password Protection by Operator Management

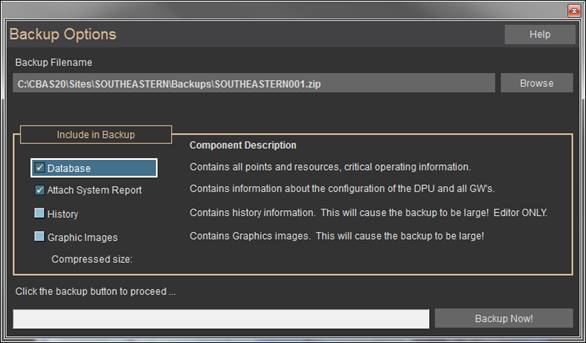

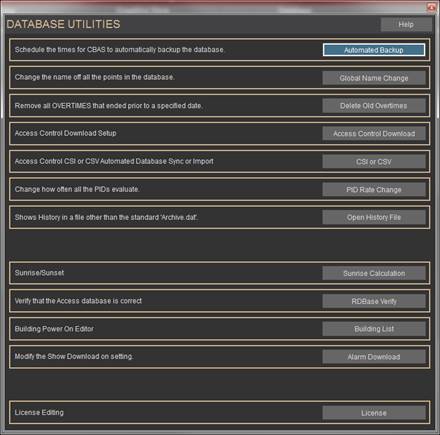

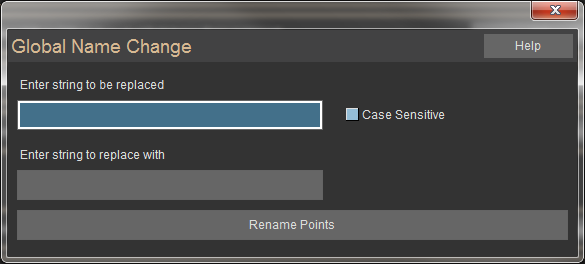

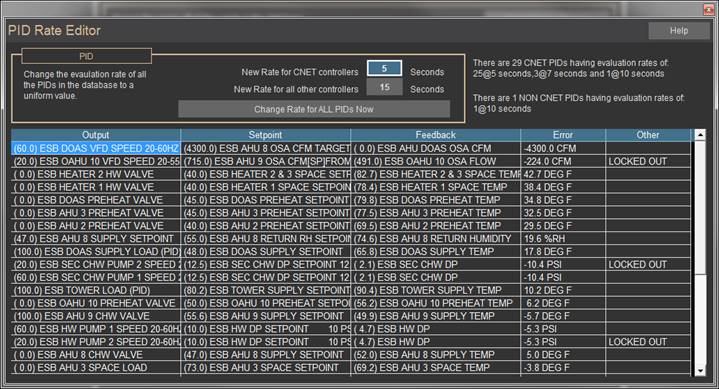

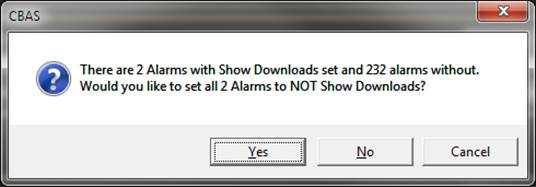

Database (Now on Database Menu in CBAS 15)

Chapter 8 » Advanced Programming.

CBAS Alarms Play Through Sound Card

Web Weather and Future Weather Point

System Points and Another way to Add Points

Troubleshooting Communications

Chapter 11 » BACnet Programming

Programming 3rd Party BACnet Controllers in CBAS

Chapter 12 » CBAS Modbus Programming Guide

More on the Modbus Generic Controller

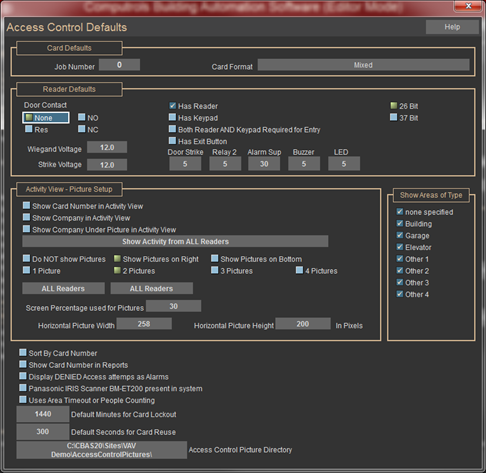

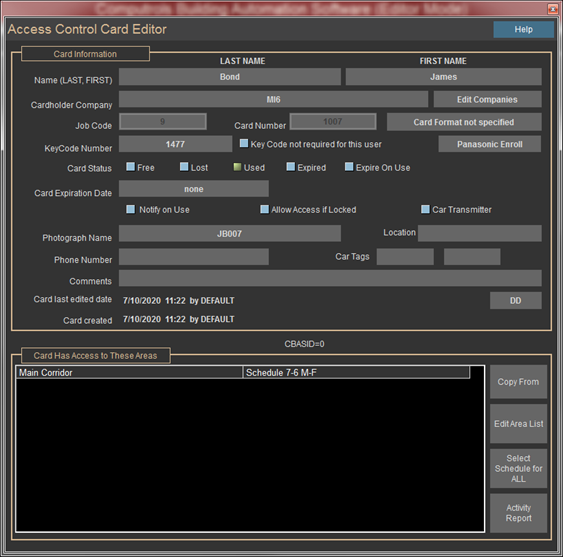

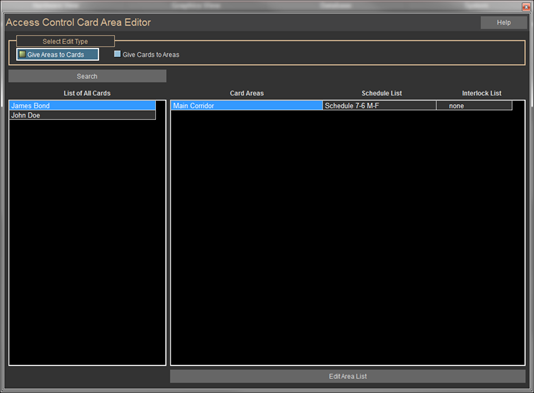

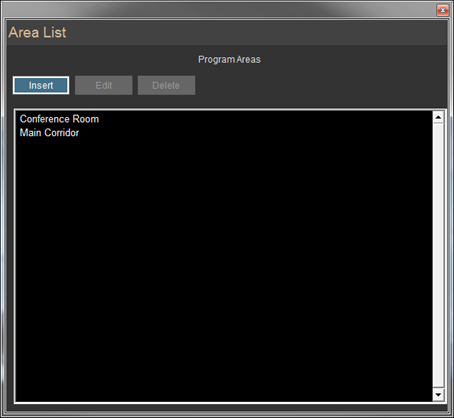

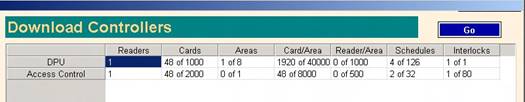

Adding Access Control to an Existing Database

Creating a New Access Control Database

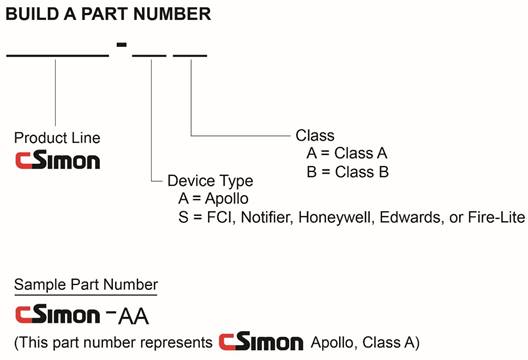

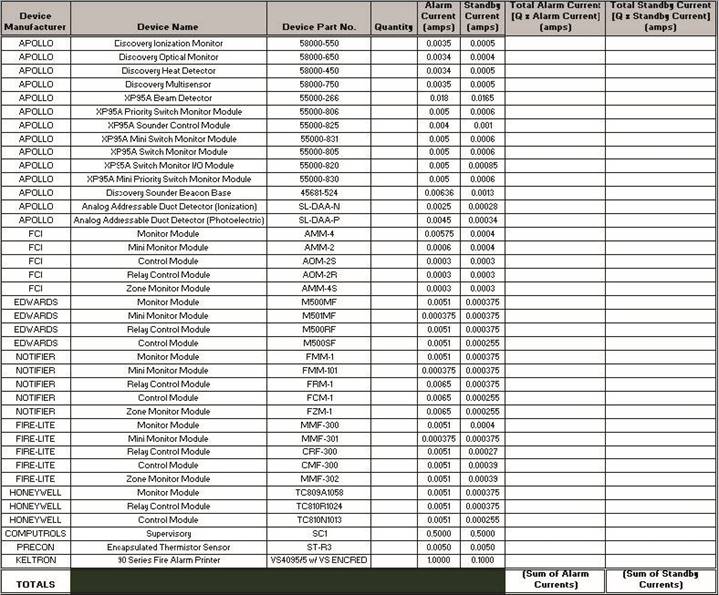

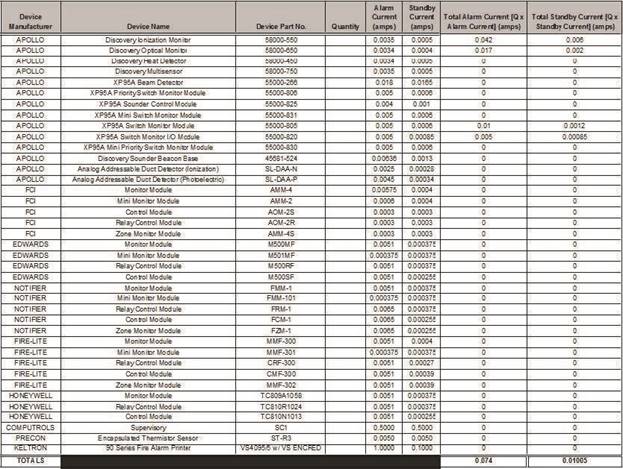

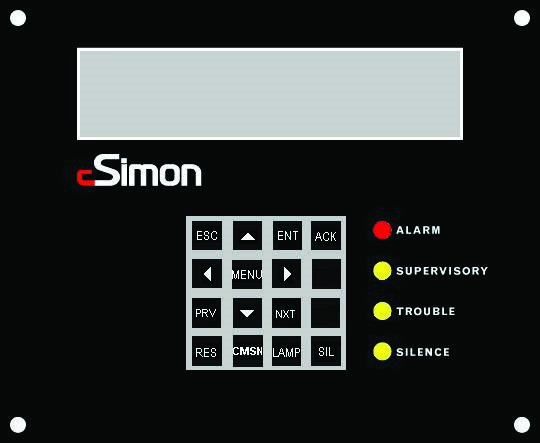

Chapter 14 » CSimon Fire Protection System

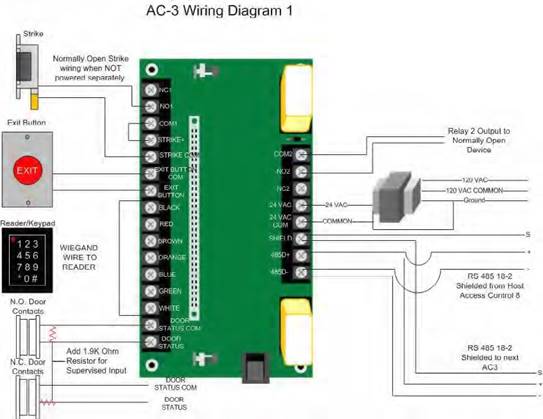

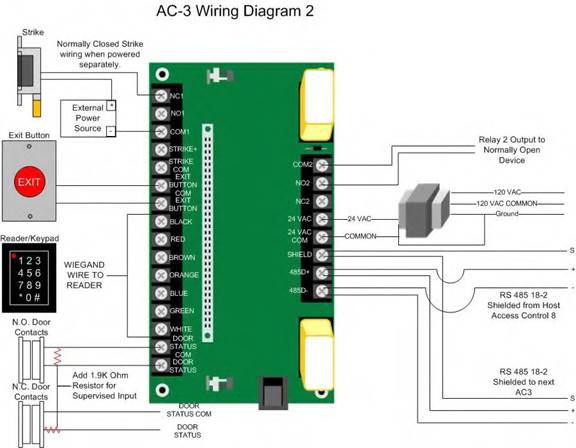

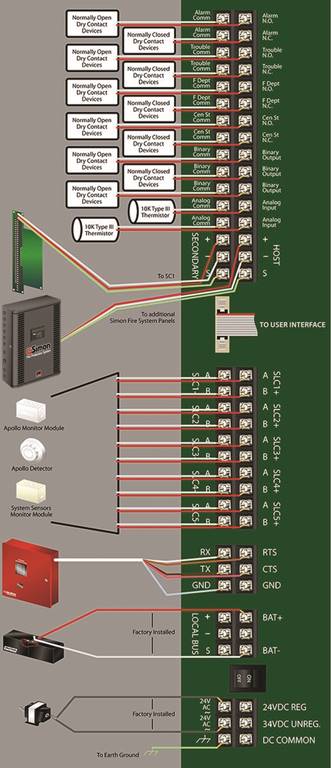

Terminal Descriptions/Installation Instructions

Chapter 15 » Smoke Control System..

Programming Smoke Control in CBAS.

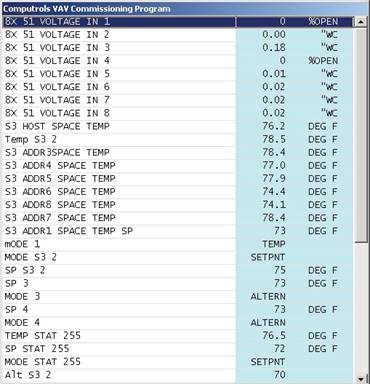

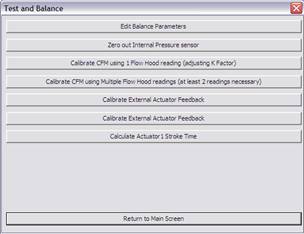

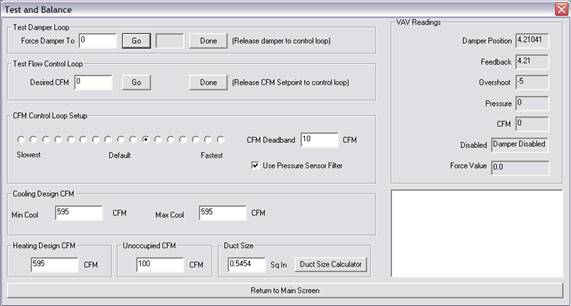

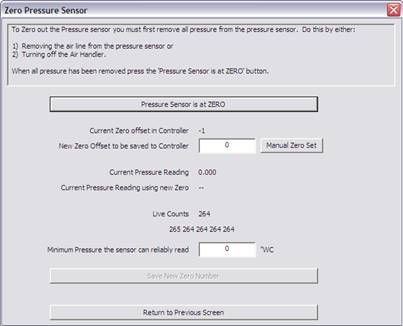

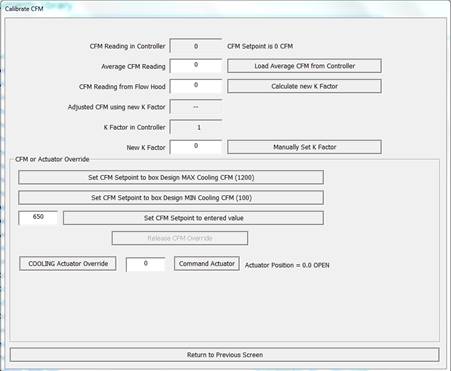

Test, Balance and Zero-Out Pressure/Damper

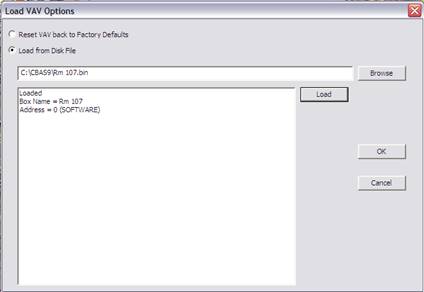

Adding More VAV-Bs from Saved Configuration File

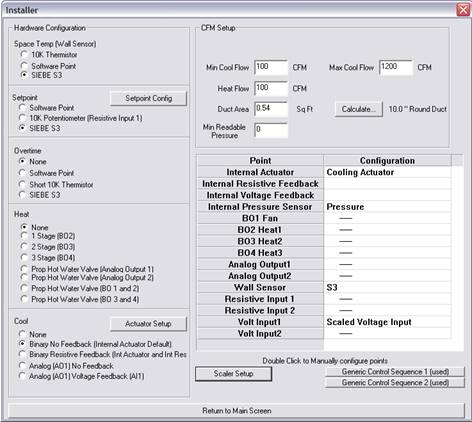

Chapter 4 » CBAS Configuration

Proceed to Real Mode and Begin Monitoring the VAV-B

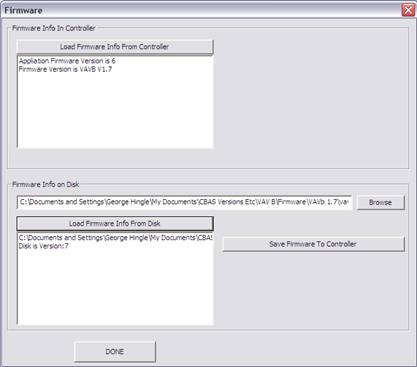

Reburning the Application Firmware.

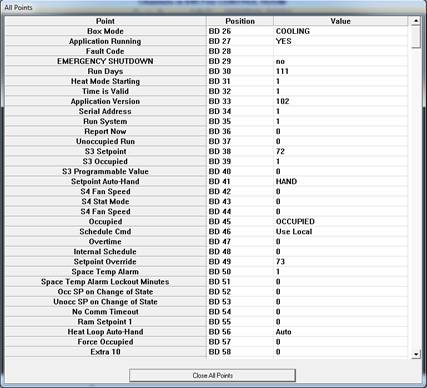

Appendix A » VAV-B Points in CBAS.

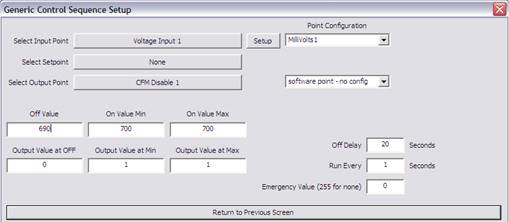

Appendix B » Generic Control Sequences

Appendix C » BACnet Points in CBAS.

Appendix D » Siemens Points in CBAS

Appendix E » Primary Air Heat Features

Congratulations on owning the most simple-to-use software in the Building Automation Industry. The intention of this program is simplicity for the operator. All commands can be done with either the mouse or the keyboard. The following terms are used frequently throughout this manual and should be understood prior to continuing:

Using the Mouse: Right clicking is equivalent to pressing the Escape (Esc) key on the keyboard, and left clicking is equivalent to pressing the Enter key. There are very few exceptions to this rule, and they will be addressed in the appropriate sections of this help guide.

Left Click: Also referred to as “Click.” When entering information, or selecting a field, left click or press enter.

Right Click: To return to the previous screen and save all changes made to the current screen, right click or press Esc.

In order to simulate logic, you can change setpoints in order make heat or cool work. However, on the Program screen of analog input points, there is a Force Output button that allows you to change a temperature etc. The button is in the top right of the Point Program screen.

This revision of the CBAS Manual was created during the release of CBAS Revision 20, so many sections only show the operation of that revision. Where there are major differences between the above version and previous versions, those will be discussed, but the main focus will be on the latest version.

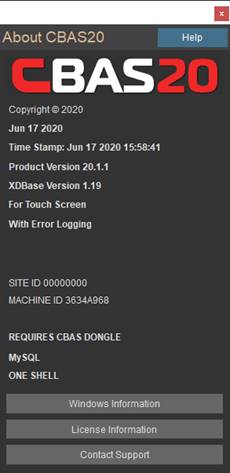

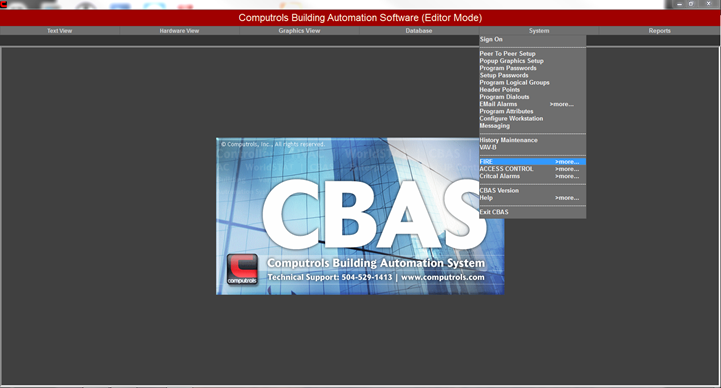

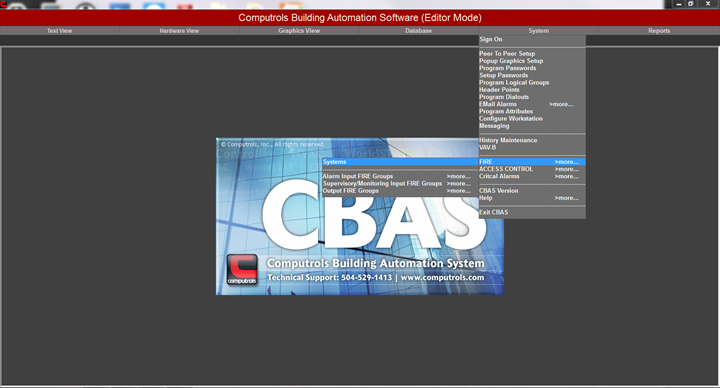

In order to determine your revision, go to the Main Menu, System Menu and then CBAS Version. The revision number will be listed as “Product Version X.X.X”. The Timestamp is the date the revision was compiled.

Two lines below the Product Version you will see one of either Professional or Commercial. These are product classes. Here is a brief explanation of the classes:

· Professional: This is the main, full-featured version of CBAS, which has no point limits and is more than sufficient for any size building.

· Commercial: This class was added to make CBAS more cost-effective for use in smaller buildings and has a limit of 10 controllers or 250 hardware points.

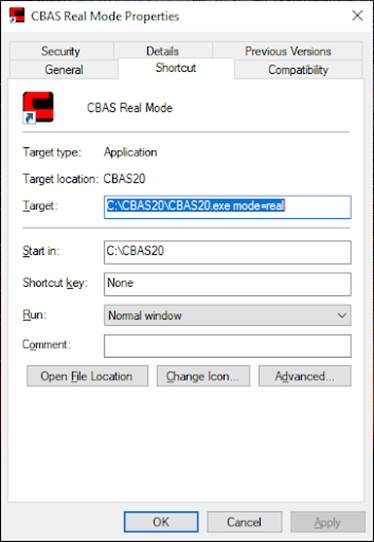

Contact techsupport@computrols.com to obtain a link to download the installer named CBAS 20 setup.exe. Right-click the file and choose Run as Administrator. This is necessary even if you think you are logged into Windows as an administrator. Otherwise, Windows could prevent certain files from being installed and that will prevent CBAS from running. Once the Setup begins, follow on-screen directions.

Once completed, use the shortcuts that were placed on the desktop the first time by right-clicking them and clicking Run as Administrator. This should prevent Windows from asking Are You Sure(?) before opening the program the next time.

When you first open CBAS, you will receive 3 errors that the database cannot be loaded. Close these errors by clicking OK. You must first Install a database by obtaining a backup either from Tech Support or by making a backup from your building’s CBAS, then going to the Database menu and choosing Install Database. Point to the backup and click Install. You must choose a backup created in CBAS 15 or a more recent version. Installing and Opening Databases is covered in detail in Chapter 2 of this manual.

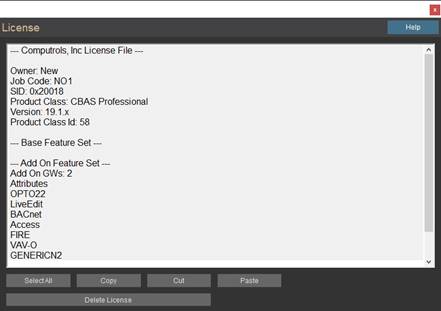

In order to enter Real Mode (next section), you must purchase a license to use the CBAS software. This is also required in order to use add-on features like 3rd party protocol interfaces and other features. You will be issued a Key-Lok (dongle), which is a hardware key that plugs into a USB slot. It works in conjunction with a license text file. Both are assigned an ID number and name of the site. The two have to match in order for CBAS Real Mode to work. The license text file is now stored in the database. The Site ID on both must match and the version on the license must match the version of CBAS that you are running, at least the first 2 numbers of the version. Like 17.1 or 19.1.

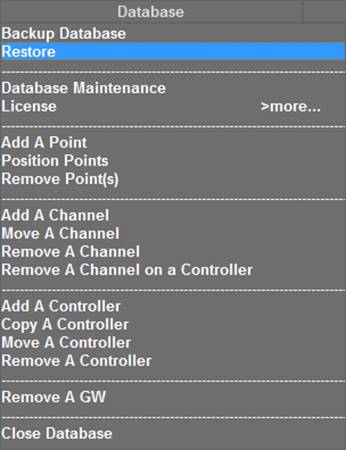

To view your CBAS license, select the Database menu and choose License/>more/CBAS (see below).

If you have upgraded your license or added a new add-on feature, you must delete the old license and restart CBAS to pick up a new license placed in the CBAS root folder. In CBAS, go to Database, Database Maintenance, and then License. There is a button below the text section to delete the License. Do not attempt to alter the text, because that will corrupt the license.

Restart CBAS in order to pick up the new license file.

If you are still not able to enter Real Mode, it might be that either:

· The Dongle Key is not installed, or

· The license is not unzipped and placed in the CBAS folder, or

· The license and dongle do not match.

To see if the Dongle Key is installed in Windows, go to the search field next to the Start Button, then type Device Manager and choose it from the list. At the bottom of the Device list you should see USB Key, then the sub item USB Dongle-Software Protection Device. If there is a yellow question mark or red X on it, then new drivers are required.

Instructions on acquiring and installing the dongle drivers, see Chapter 9, Section 3: Installing Dongle Drivers.

· CBAS 15 runs in the CBAS 15 folder.

· CBAS 15 will no longer be compiled for Windows XP or Vista. The reason is that now CBAS Graphics View has been made more touchscreen friendly. In addition, the touch screen functionality only works with Windows 7 or 8, 64-bit version. If you have 32-bit Windows, CBAS 15 will work but some of the touch screen functions will not.

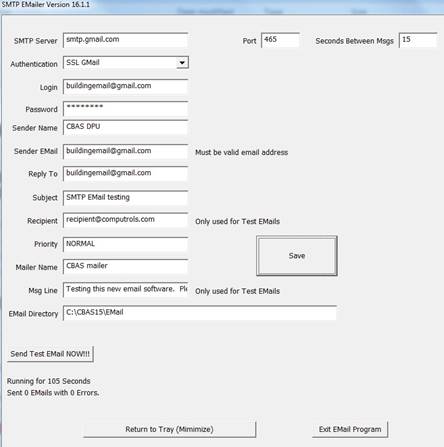

· SMTP Emailer and CBAS Logger now run as a service. These are explained in later sections and the new Computrols Support Service is explained in Chapter 7, Section 13, Web Weather Points.

· You are required to change the Computrols user password when upgrading a database.

· CBAS 15 now uses MySQL as the database for passwords, logical groups, and graphics instead of Microsoft Access.

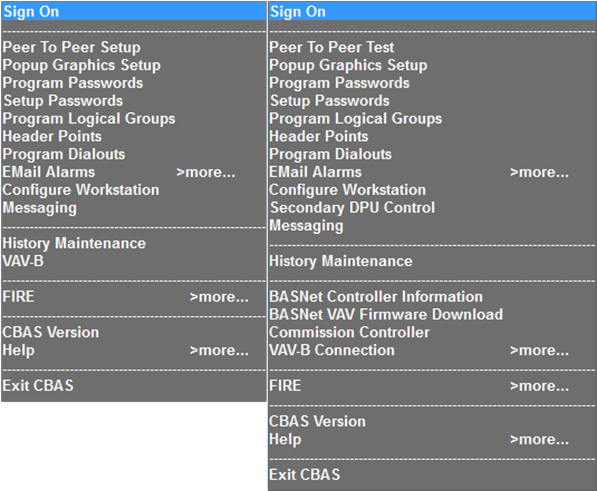

· Menus have changed. Most notably, the Database menu is now present in Real Mode and anything database related, like Backup or Close Database, have moved to this menu.

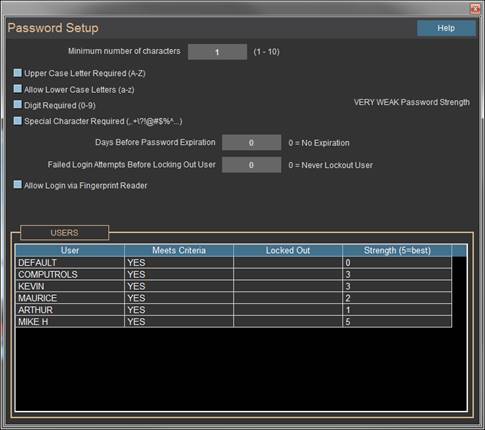

· You can now choose to make passwords more secure. See detailed instructions in Chapter 5, Section 7 – Setup Passwords CBAS Simulator. Previously, you could only simulate 1 BASnet controller at a time. Simulator mode works great now for databases of all sizes.

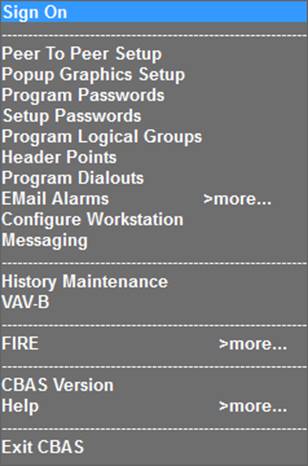

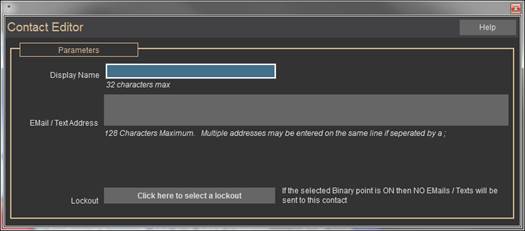

· Added a Copy Email Alarm button which copies the setup of the contacts to new points. Increased the number of Header Points allowed in CBAS from 2 to 10.

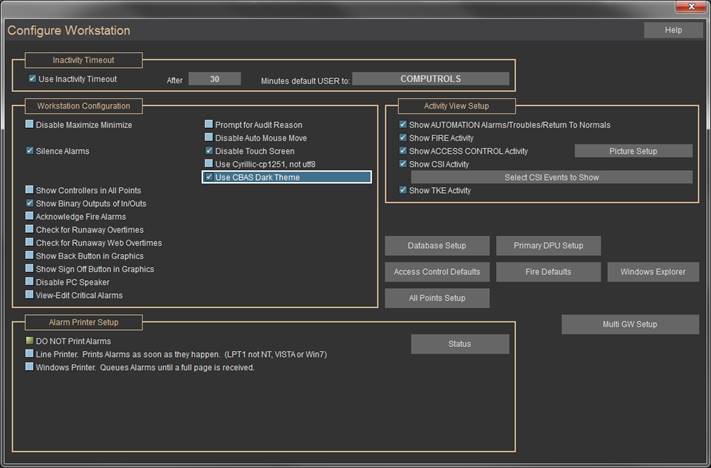

· Added GW Graphics Directory in Configure Workstation. Now from a GW you can set the Graphics Relative Path Prefix.

· Graphics paths are now relative paths to the database. This will change in CBAS 17. The Decimal Places for Analog points have been moved to the More button.

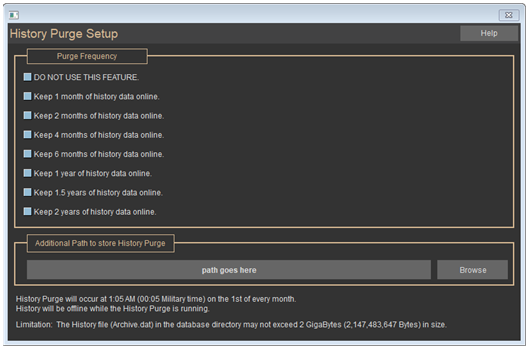

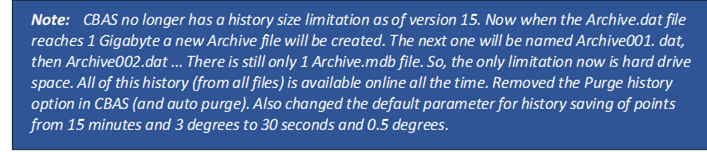

· CBAS no longer has a history size limitation. See History Maintenance All software points in the DPU are shown in Editor Mode.

· Added new features to the Text View Search feature.

· Added button in Configure Workstation to disable the double click – auto mouse moves feature in CBAS.

· CBAS 17 runs from the CBAS 17 folder.

· Databases can only be run from the C:\CBAS 17\Sites or C:\CBAS19\Sites folder.

· Enhanced passwords allowed using Setup Passwords on the System Menu. Chapter 5, Section 7.

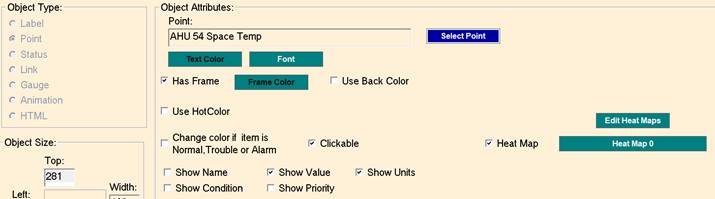

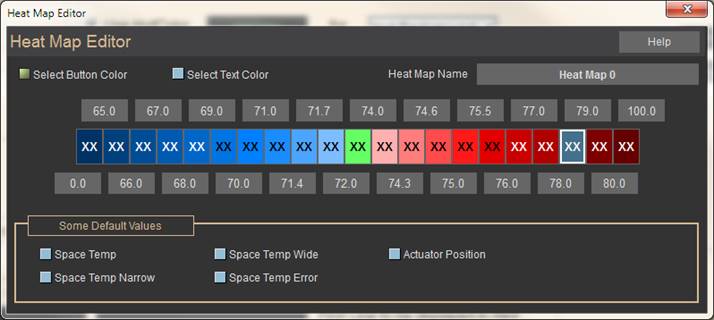

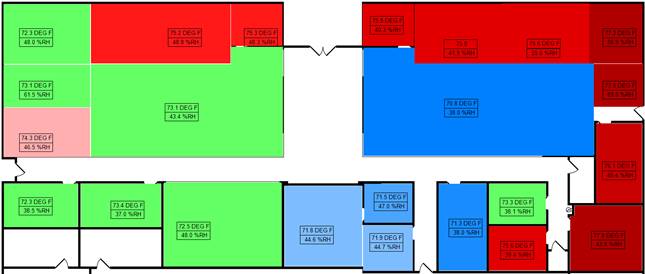

· Heat Maps in CBAS Graphics.

· No History Size Limitation and lower default History Save Settings.

· Text View, All Points can now be scaled to increase or decrease font size, allowing more or less points to display.

· There is a new Graphics engine which allows more graphics formats including transparent PNGs and animated GIFs. Also, Menus display properly on multi-monitor systems.

· You can now setup email alarms to only go out to users while they are on their shift.

· In addition to Web Weather Points, CBAS now has Future Web Weather Points that give you forecasts.

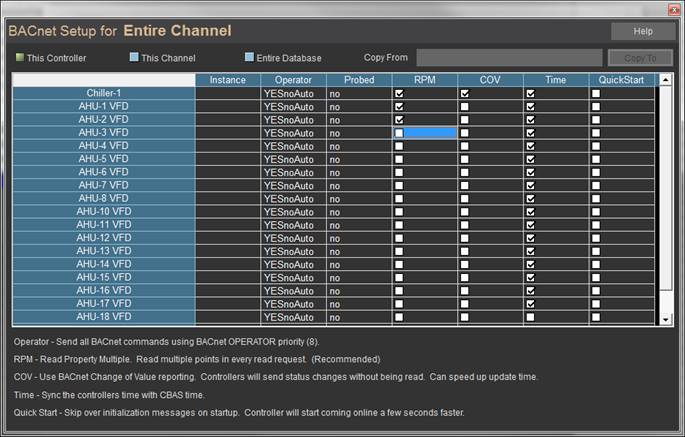

· There is a new BACnet Setting feature that allows you to copy settings like Instance, Change of Value and Read Multiple to other controllers that haven’t been Probed.

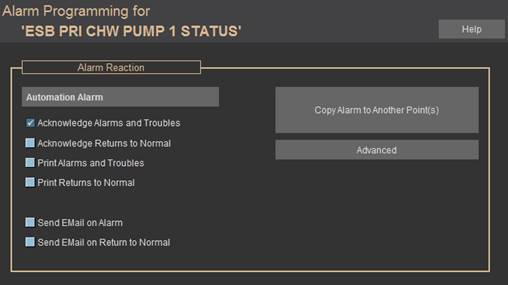

· You can now setup Email Alarm and add Contacts directly on a Point’s Alarm Setup screen.

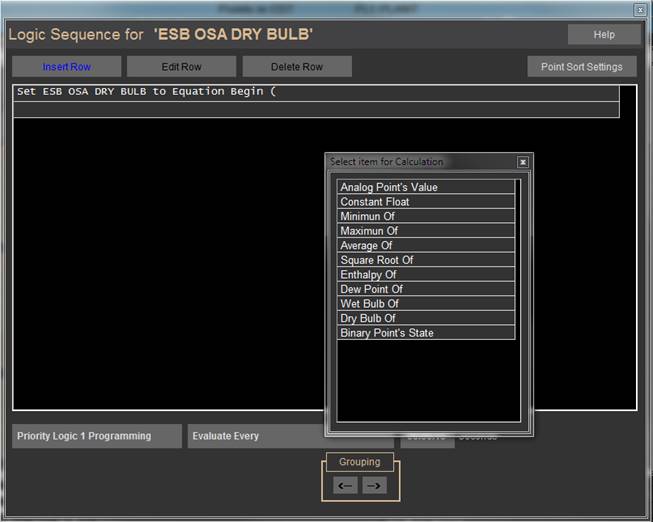

· There is now a Dry Bulb Calculation in Logic.

· Alarm Report now has a choice of the old report and a new grid style report with all parameters.

· Added Alarm Activity Report with Acknowledgments that can auto-email daily.

· Stulz Protocol. CBAS can be run as a Service.

· Now CBAS has a dark color theme and you can toggle between traditional CBAS colors and the dark theme.

· Dual Monitors.

· Email Tech Support.

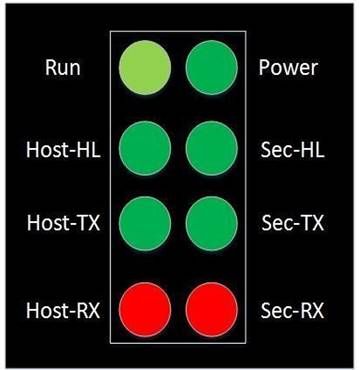

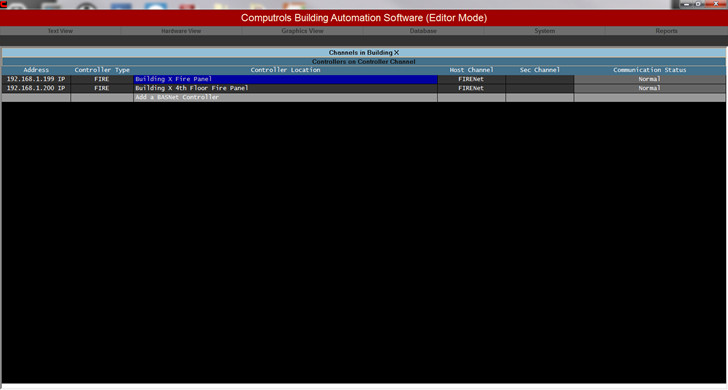

· Hardware View now includes Host and Secondary Channels.

· Per Channel Licensing.

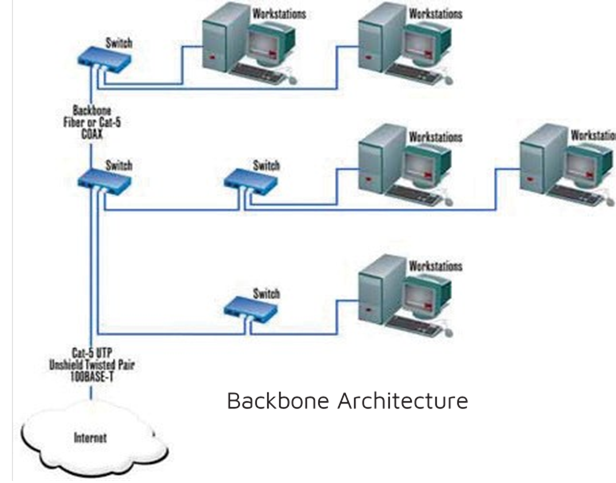

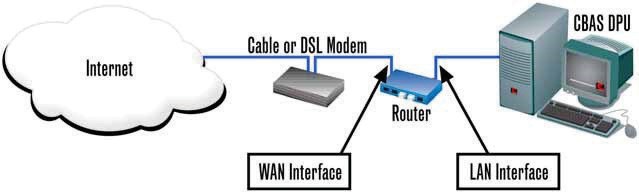

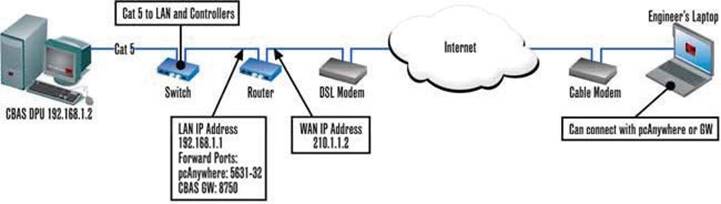

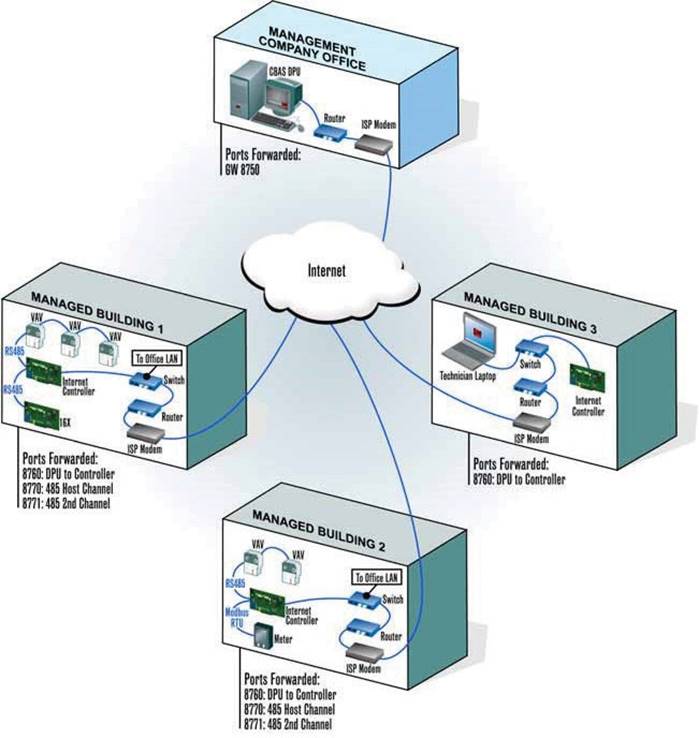

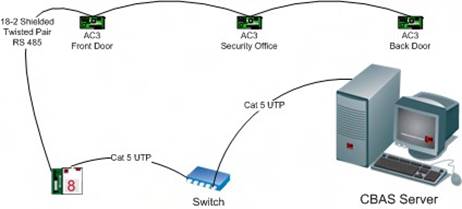

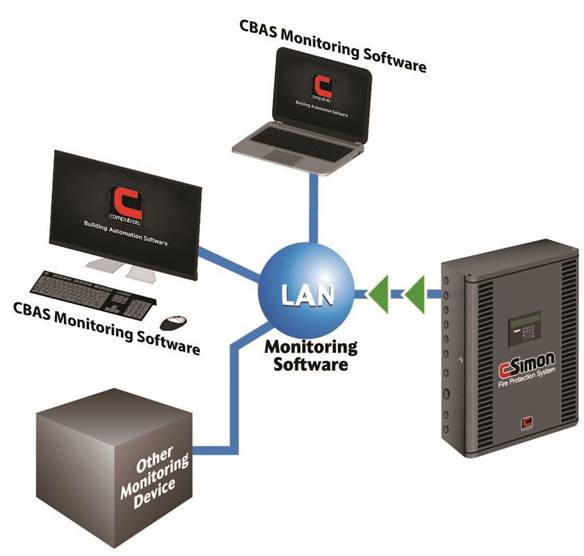

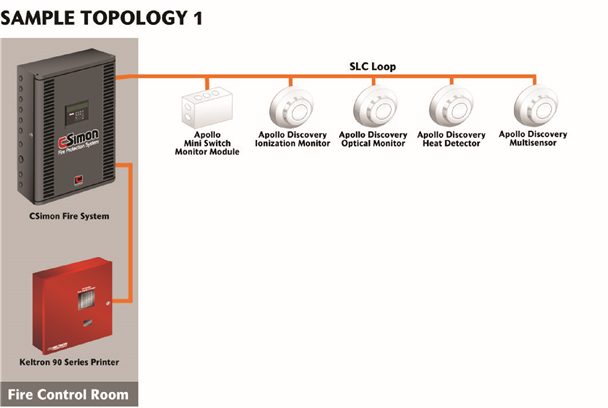

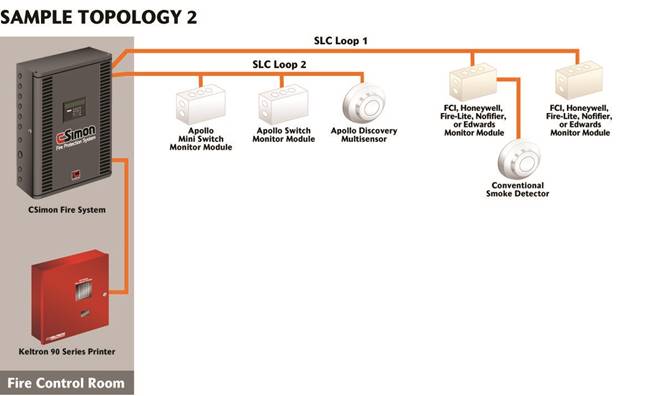

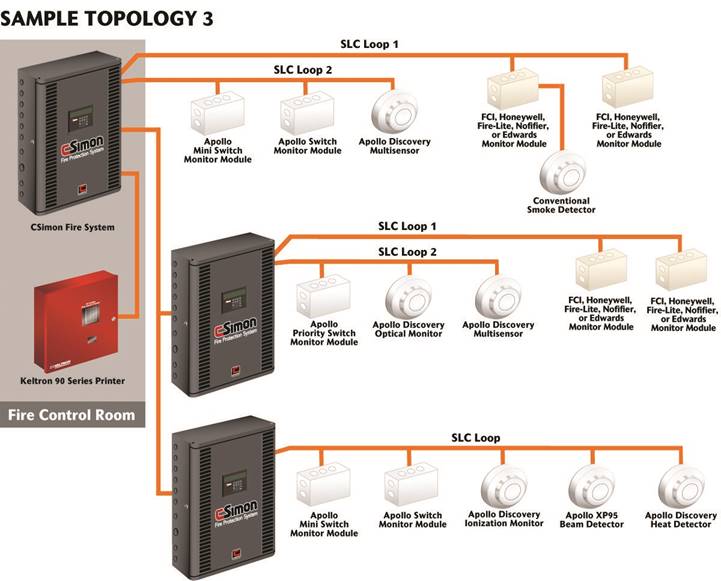

More network topologies can be found later in this manual under Sample Wiring Layouts.

![]() Chapter 2 » Getting Around CBAS

Chapter 2 » Getting Around CBAS

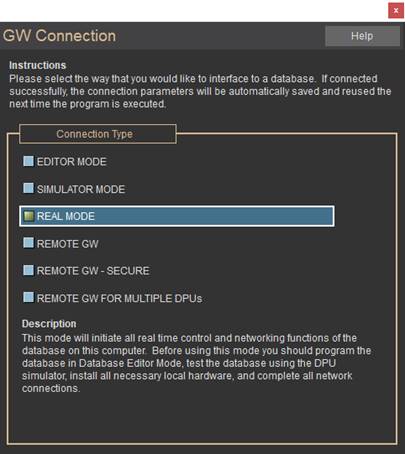

You can run CBAS in Real Mode, Editor Mode, Simulator Mode, or Graphic Workstation (GW) Mode with each mode allowing different capabilities.

Real Mode is the only mode where communication is enabled between the CBAS computer and the controllers and workstations in the database. Consequently, this is the only mode where On Scan and Off Scan work. Points can be commanded On, Off, and Auto. All programming of Channels, Controllers, and Points can be done in Real Mode, including Logic, Schedules, PIDs, Alarms, etc. Points can be repositioned in Text View. On the System Menu, some statistics and controller information can be obtained.

When viewing Controllers and Points in Hardware View using Classic CBAS Color Theme, the columns on the right side will be a blue color when Normal Communication is present, and yellow when communication is Lost. Using the new Dark Color Theme, the points will be dark gray when Normal and yellow when lost.

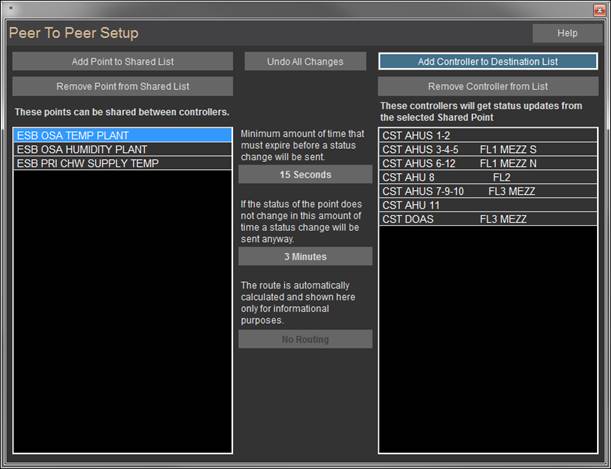

The Database Menu did not exist in Real Mode prior to CBAS 20. Adding Channels, Controllers, Points and Workstations is not possible in Real Mode. However, an add-on feature (Live Edit) to your license will allow you to add points in Real Mode. Peer-to-Peer cannot be configured in Real Mode.

Editor Mode is used for creating databases, adding and removing Channels, Controllers, and Points, while also configuring Peer-to-Peer. The computer does not communicate to the controllers in Editor Mode. The Database Menu exists only in Editor Mode.

Simulator Mode allows you to test logic and other programming by simulating Real Mode. In CBAS 20, Simulator Mode was improved to be able to simulate all controllers in the database. Prior to this, you could only simulate 1 controller at a time. When Simulator Mode is started, you are required to select the 1 controller you want to simulate. CBAS 20 allows you to simulate an entire database of controllers.

In order to simulate logic, you can change setpoints in order make heat or cool work. However, on the Program screen of analog input points, there is a Force Output button that allows you to change a temperature etc. The button is in the top right of the Point Program screen.

Graphic Workstation Mode (GW) allows a workstation computer with CBAS installed on it to connect to and share its database. A GW is used to monitor a database, but not to make major programming changes. Adding and removing Channels, Controllers and Points, as well as some administrative functions, are not possible on a GW.

These are the things you can’t do from a GW:

· Adding and Removing Channels, Controllers, and Points

· Editing Graphics

· Edit Logical Groups - Only seen on GW

· No other administrative features on the System Menu work

Except:

· Access control menu is available

· Header points: Works for GW only, doesn’t change DPU

· For instructions on opening databases in these different modes, see the next section, Databases.

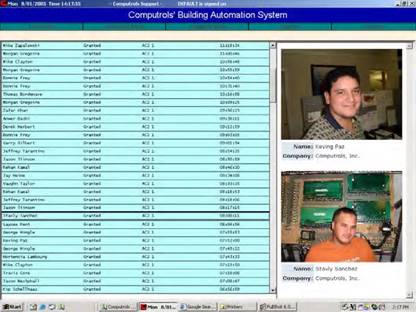

The term for a Workstation in CBAS is GW (Graphical Workstation). On the DPU or Automation Server, the CBAS software runs the Database for the building in Real Mode and communicates to the Controllers at the site. Workstations connect to the DPU and basically share the database.

From CBAS on the GW, you can do most everything that can be done on the DPU: command points; change Logic, Schedules and PIDs etc.; run reports; add and remove Access Control Cards; add users etc. Some things you can't do from GW are make backups, add and remove controllers, points and channels, etc.

By default, CBAS Professional allows up to 2 GWs to connect at one time. You can program as many as you want in the Workstation Channel, but only 2 can connect. However, additional GWs can be purchased and added to the site license giving the building more.

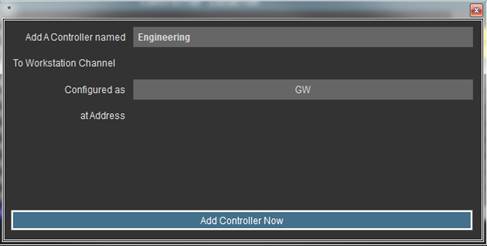

Generally, when the database is first programmed and the controllers commissioned, 2 GWs are added to the database by the technician doing the installation. To add GWs to the DPU, go to Editor Mode then Hardware View, click the Workstation Channel then Controllers. On a new database, you will only see the Local GW, which is really the graphical interface to the DPU running in Real Mode, and always shows that it has Normal communication. Click Add a GW/Stringserver.

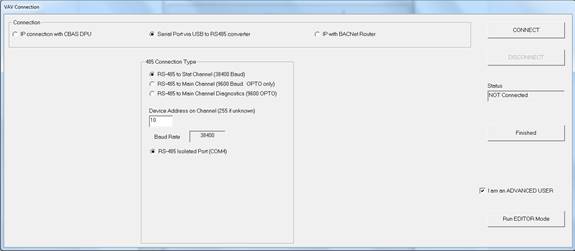

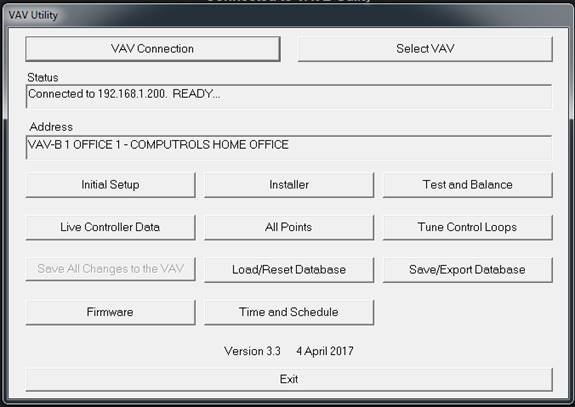

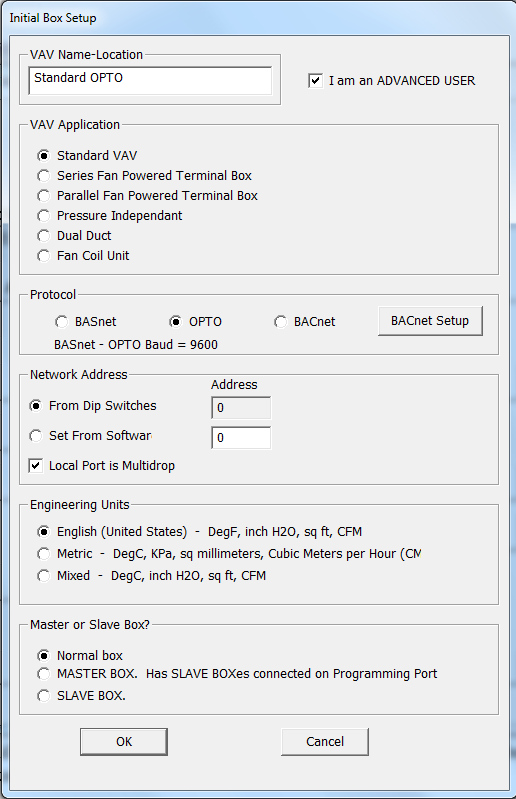

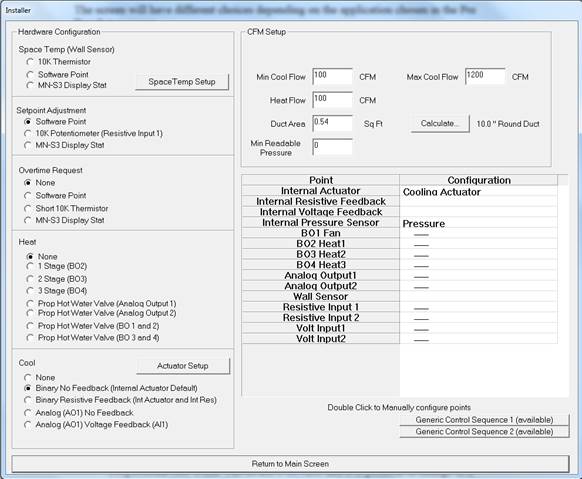

Give it a name that indicates where it is located or who is using it, then choose GW for the configuration and click Add NOW! Under Configuration, there are other choices: You can also add a Stringserver (allows a CBASweb Server to connect) and VAV-B Commission (connects and opens the VAV-B Utility Program). Once you have added all needed GWs, escape from the Workstation Channel screen then click it again and click Program. On this screen, make sure the IP address listed is the IP address of the DPU's network card. You can get this by opening a Command Prompt and typing ipconfig/all then Enter. If you have more than one IP address, make sure you enter the one that is on the subnet where the GW computers are. Otherwise, CBAS doesn't know which network card to reply back to, so it might choose the wrong one. Once entered, escape and you can return to Real Mode. You can change the IP address in Real Mode but you have to restart CBAS after.

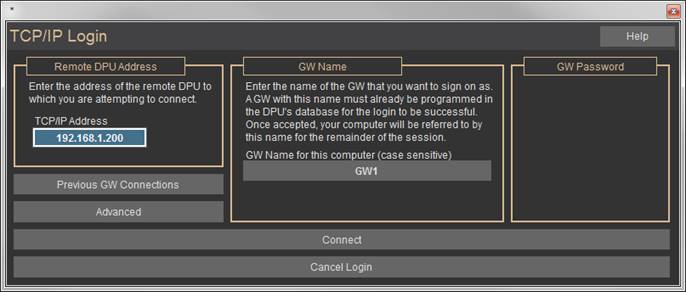

To connect a GW, you must have CBAS installed on another computer. The version of CBAS must be very close to the same version as the DPU. To see what version is running on either the GW or DPU, go to System, then CBAS Version and note the Product Version. If you are not on the same version, you can close CBAS and copy the CBAS 20.exe from the C:\CBAS20 folder on the DPU and copy it to the same location on the GW.

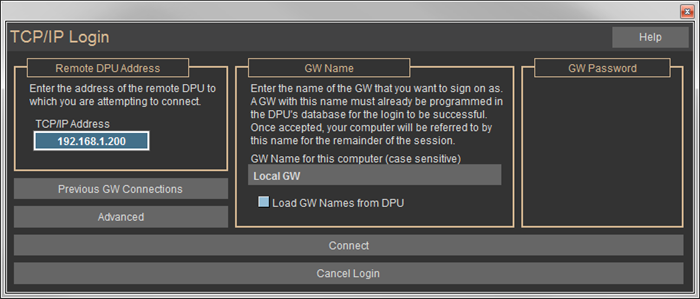

When you open CBAS on the GW, it will probably open in Editor mode. If a database opens, close it by going to Database, Close Database. Once closed, you will only see Database and System on the Main Menu. Click Database, then Open Database and choose Remote GW.

Type in the IP address of the DPU then check the box to Load GW Names and wait. If successful, you can click the dropdown list above and choose a GW name that is not already connected. The list will tell you which ones are not connected. If they are all connected, then you need to add more GWs to the DPU. After choosing a GW, click the connect button and give it a minute to download, then you can begin using CBAS.

There are a few things that can prevent the connection.

· The DPU might not be in Real Mode.

· If you get a TCP\IP error then you might have the wrong IP address for the DPU or there could be a network problem preventing the connection.

· It could also be the Windows Firewall on the DPU. Turn off the firewall or make an exception for incoming IP Port 8750. If the CBAS version is 15 or later, you also need to open port 3306 for MySQL.

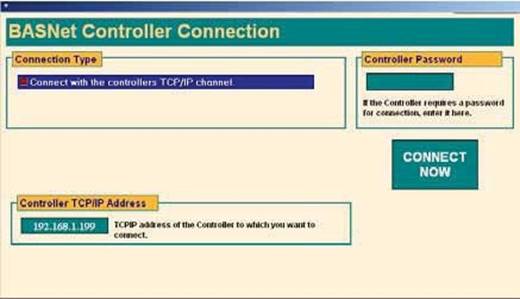

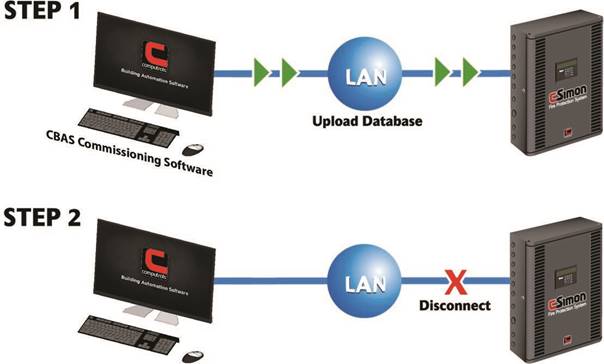

What happens when you get to a site where you only have a standalone controller and you forgot the database because you just moved into a new laptop? One choice is the Commission Program, which is covered in the Troubleshooting section under Commission Program. The other choice is CBAS “TCP/IP Connection with Controller.”

![]()

The directory structure for Databases has changed as of CBAS 19 and CBAS 20.

Databases are now contained in CBAS20\Sites\[Database Name] or CBAS20\Sites\[Database Name]. Under the [Database Name] you will find separate folders for Database, History, Graphics, Backups, System Log and a few others. If your Database was named "Computrols Building" for example:

C:\CBAS20\Sites\ComputrolsBuilding\Database\ - contains all database files and folders.

C:\CBAS20\Sites\ComputrolsBuilding\History\ - contains all History files.

C:\CBAS20\Sites\ComputrolsBuilding\Graphics\ - contains all Graphics background pictures and animation files. No sub-folders can be used.

C:\CBAS20\Sites\ComputrolsBuilding\Backups\ - contains any backups that are made manually or automatically.

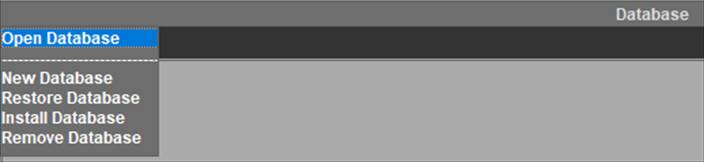

Also, the Database Menu when Opening and Restoring Databases has changed. When you don't have a Database open, the Database Menu now shows:

· Open Database

· New Database

· Restore Database

· Install Database

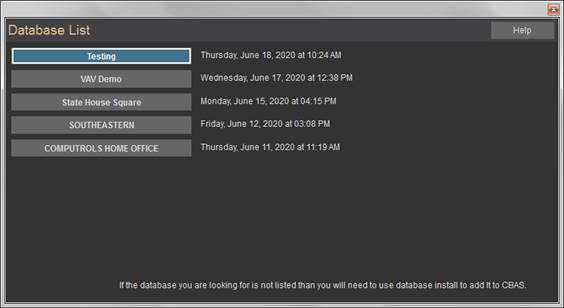

· Remove Database

When you select ‘Open Database’ you can choose Real Mode, GW Mode, Editor Mode or Simulator Mode first, then you will be given a list of Databases to choose from that have already been Installed into this Computer. You will only be able to select from this list. If you only have 1 Installed database, then Open Database will skip this step and just open that database (there is nothing to choose from).

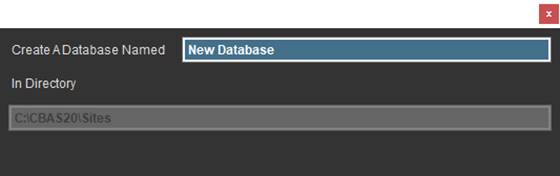

'New Database' allows you to create a new Database from scratch. All folders are created for you under Sites and it will show up on the list of Installed Databases.

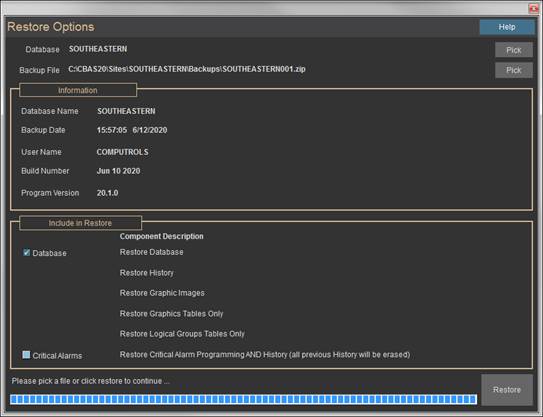

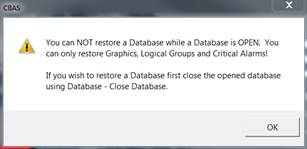

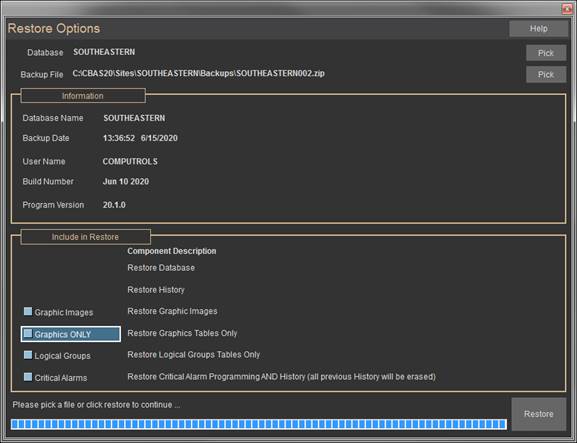

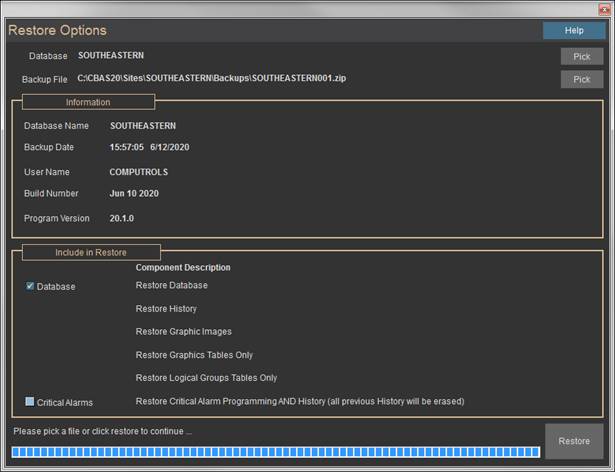

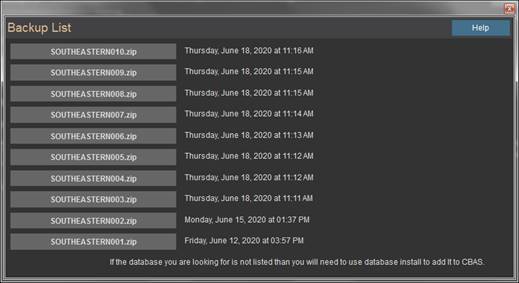

When you select 'Restore Database' you will see a slightly different Restore Options screen. If you have only one Installed Database, it will select the most recent backup. The same is true for the last Database you opened. If you click the PICK button in the top right, it will take you to the list of Installed Databases. Click one and it will find the latest backup and put the path on the next line. Click the second PICK button and you can select another backup from the list.

'Install Database' is used to add a database or upgrade a database. In order to do this, you need to place a CBAS 15, CBAS 17, CBAS 19 or CBAS 20 backup in CBAS20\Backups folder. Actually, you can browse to the CBAS20\Backups folder too. When you click Install Database, you will see a different version of Restore Options. Click PICK, browse to the Backups folder and select the Backup file, then Click Restore. CBAS will create all the folders for you.

Clicking 'Remove Database' will take you to the Installed Database list where you can select a Database to remove. You might want to copy the Backup and Graphics folder to another location before completing the remove procedure. CBAS does not remove the files and folders, just renames the [Database Name] to removed_date_removed. If you want to permanently remove a DB you would have to use File Explorer and manually delete the directory under sites. If you want to undo the removal of the DB (restore), then use File Explorer and remove the 'removed' string before the database name and next time you start CBAS it will be there.

To upgrade a Database from CBAS 14 or earlier:

· Open the Database in CBAS 14 then close CBAS 14. It is advised that you run Debug to clean up any corruption first and run Verify RDatabase for corruption in Logical Groups.

· Copy the Database folder from CBAS to CBAS 20 and open the Database in CBAS 20.

· Make a Backup and this can be used to “Install” the Database in CBAS 17, 19 or 20.

To open a database in legacy version prior to CBAS 17:

If CBAS is not already open, click on the CBAS Editor, CBAS Real, or CBAS Simulator icon on the Windows Desktop. The last database that was opened will open in the mode you selected. If you do not have an icon, go to Start, Programs, CBAS, and CBAS. The database will open in the Mode it was opened in last.

If CBAS is already open, hit ESC until you get to the Main Menu.

· Click System and click Close Database. You will only see Database and System on the Main Menu.

· Click Database and click the mode that you want to open. Starting in CBAS 15, Close Database and other Database functions are located on the Database Menu now available in Real Mode.

The following window will appear after you click Open Database:

· From the connection screen, choose the way you would like to interface with the database – Editor Mode, Simulator Mode, Real Mode, or Remote GW.

· For Editor, Simulator and Real Modes, you will see a Browse for Folder dialog box. Select your database from the tree in the Browse for Folder window. The database folder must be located in the C:\CBAS20 folder (or C:\ CBAS 2000 folder, for versions prior to 2.1.0). Do not choose a sub-folder of the database, as those are individual controllers and cannot be opened. Click OK and the database will open in the mode you selected.

· Once the operation mode is selected, the Database List dialogue will appear. This dialogue will allow you to select from all available databases on the DPU.

To change modes, simply close the database from the System Menu, and follow the “If CBAS is already open” directions above. Or, simply close CBAS and reopen using the Editor or Real Mode shortcuts.

For instructions on Remote GW Connections, see the Graphic Workstation section.

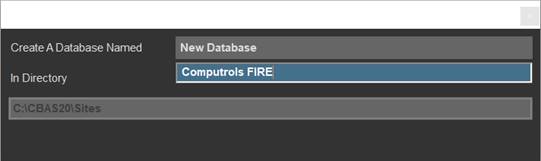

To create a new database:

· If you have a database open already, click Close Database from the System Menu.

· From the Database menu, click New Database.

· Enter a descriptive name for the database.

· You cannot select a location for the Database because CBAS 20 will place it in CBAS20\Sites.

· Hit Enter and a folder will be created for your new Database.

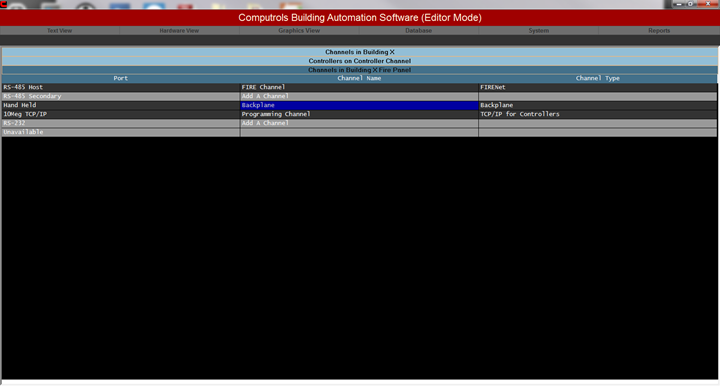

After a short time, the new database will open in Editor Mode/Hardware View. The only existing channels in the new database will be appropriately named TCP/IP for Workstations Channel and the TCP/IP for Controllers Channel. You can now create Channels, Controllers and Points, in that order. For instructions on Adding Channels, see the Channels section.

For information on opening a database from a backup, see the Backups section.

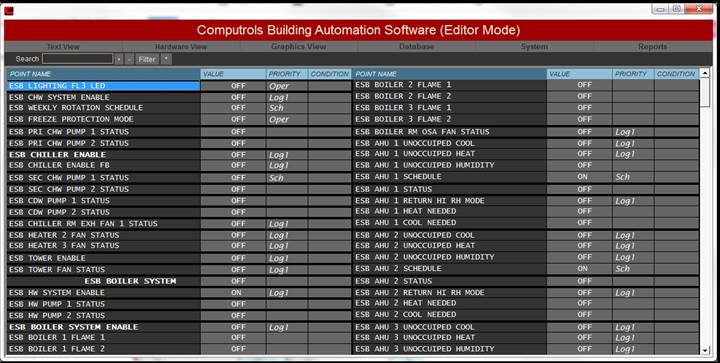

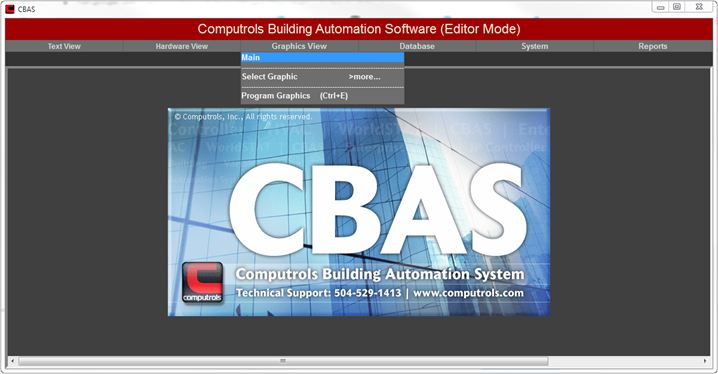

CBAS provides three ways to view your data: Text View, Hardware View, and Graphics View. Each of these views is unique in the way you look at and manipulate the system, but you can accomplish the same tasks from any view.

To view a database, left-click on the view you prefer from the Main menu.

![]()

This view contains a list of points sorted and filtered by your specifications. The figure below shows a Text View of all the points measured by a status of ON or OFF.

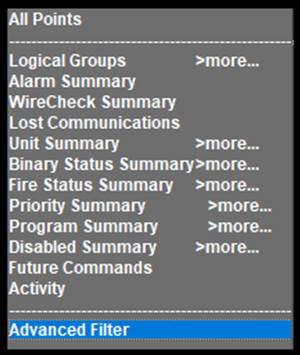

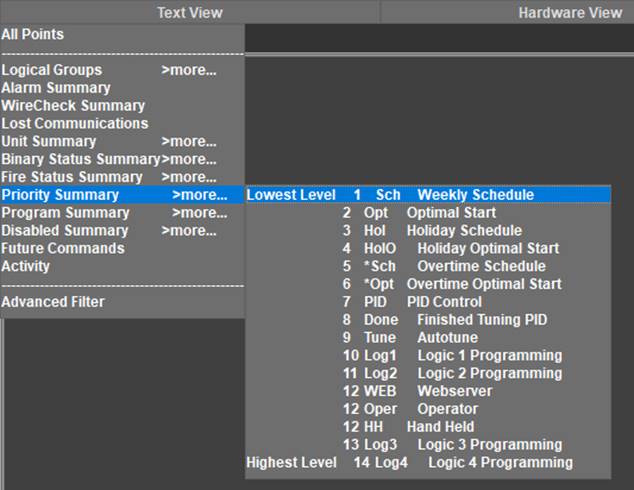

Text View allows you to sort and view a list of points that share a common attribute. When you click Text View, a drop-down menu lets you choose to view All Points in the system, create or edit a logical group, or view a group created by CBAS.

Items in the menu that have a double arrow (>>) beside them display a drop-down menu of sub-groups from which to select:

Display every point in the system in the order that the points were added. The points may be repositioned one at a time from the Text View Point Positioning button on any Point Program screen, or from Position Points on the System Menu. (Discussed in the System Menu Section)

When viewing Points in Text View using Classic CBAS Color Theme, the columns on the right side will be a blue color when Normal Communication is present, and yellow when communication is Lost. Using the new Dark Color Theme, the points will be dark gray when Normal and yellow when lost. Remember, communication to Controllers only occurs when in Real Mode. Also, the same colors are used in Hardware View for Controllers on a Channel and the Points on Controllers.

What is Priority in CBAS?

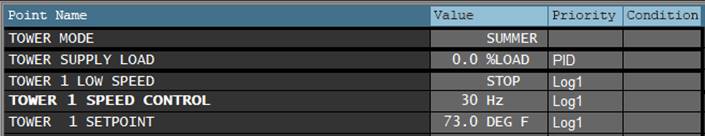

When you look at the list of points, either in Text View or Hardware View, you see the Point Name on the left. To the right of that is the Status of the Point, and to the right of that is the Priority of the Point.

Status is either the value that the sensor is sending back, or in the case of an output, whatever the point was commanded to. Priority only applies to outputs, because inputs cannot be commanded.

In the previous picture, Tower Mode has no Priority, so it is either an input or it has been "Autoed" and nothing has commanded it since. When you click an output point and click AUTO, it removes the Priority until something else commands it. That something could be one of many things:

OPER means an Operator (someone at the computer) has commanded it. This Priority means it is no longer automated because OPER overrides most Logic and all Schedules.

SCH means it was commanded by a Schedule residing on the point. Schedules only evaluate and command once a minute. It doesn't get commanded again if it is already in the scheduled state.

LOG1 means it was commanded by Logic Level 1 residing on the point or another point. Unless the conditions of the Logic are met, the Point is not commanded and the Priority will remain blank if you Autoed it.

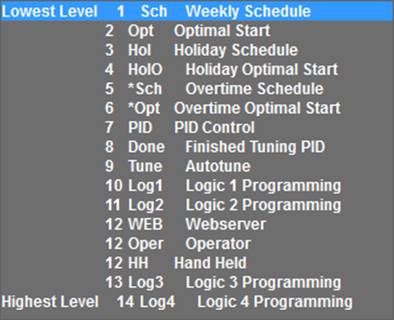

As you can see, some Priorities override others and that's why it's called Priority. To see what overrides what, in CBAS go to Text View, then Priority Summary.

Notice that Weekly Schedule is the lowest Priority and everything else can override it. Also notice that a few other schedule type features can override it also, like Optimal Start, Holiday Schedule and Overtime. When these features finish running, they AUTO, allowing the Schedule to take over again.

7, 8 and 9 have to do with PIDs which command Analog Outputs like Chill Water Valves and Dampers. 8 and 9 have to do with Auto-Tuning a PID, which is a feature on the PID Program screen. This is designed to optimize the settings of the PID.

Logic 2 can override Logic 1. The reason for this is if you need to use one Logic for one situation and another to override that Logic in another situation. Once the conditions are no longer met for that second situation, you must write the Logic to AUTO the point so that the lesser Logic can take over again.

Notice that the next three are all Priority Level 12. That means they can override each other because they are equal, and they can override everything else that is a lower Priority. They are all Operator commands from different sources: CBASweb, CBAS and the Handheld Programmer that plugs into a X or LX controller.

The final thing to understand is that the only Priorities that can override the Operator Priorities are Logic 3 and Logic 4. If you have a critical Point that you don't want an OPER to override, you make your Logic level 3 or 4.

One other thing about Priority Summary is that you can click on these Priorities on the list and see what points are commanded by that Priority. So, if you want to see every point that has been overridden by OPER, click it. It will be mostly Setpoints, but you might find a Valve, Damper or AHU Fan Start Point in that Priority and might need to be "Autoed".

There is a feature that allows you to increase or decrease the size of the Points to fit more or less Points. This was added because building managers now like to put CBAS on a large wall mounted monitor to view in the engineering office. Sometimes the Points are too small and that makes it hard to read. Other times, you might want to fit more Points on the screen.

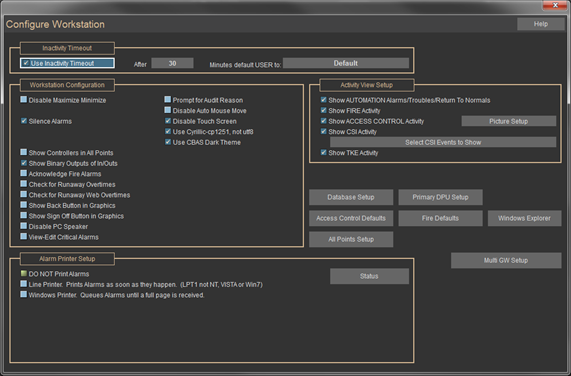

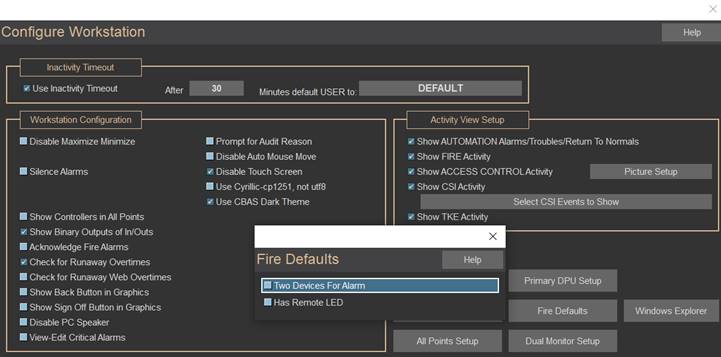

This feature can be found on the System Menu under Configure Workstation. In the middle left of that screen, click the All Points Setup button. Then click the Font Size Adjustment button.

When you click that button, you get a drop-down list of scaling choices. If you choose one of the + choices, the points will be larger and fewer will fit on the screen. If you choose one of the – choices, text will be smaller but more will fit on the page.

Once you make a choice and exit Configure Workstation, a popup will appear telling you to restart CBAS. Do that then check All Points to see if you like it.

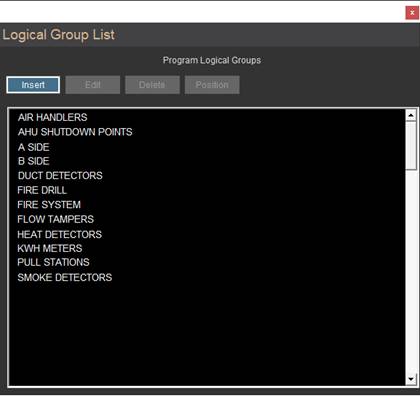

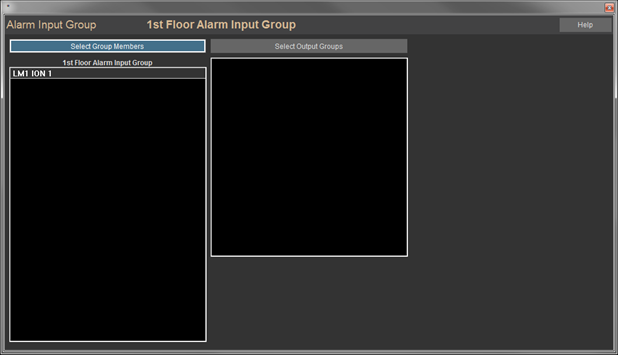

Create a new group based on whatever criteria you choose, edit or delete an existing group, or view the points in an existing group. To view a group of points, click the group you wish to view. To edit, delete, or add a new group, click Edit Logical Groups on the Logical Groups sub-menu:

Insert: Create a new Logical Group. When you click Insert, a red line and a plus symbol will accompany the cursor. The new group will be positioned in the field below the red line. The new group must be positioned above an existing group.

Edit: Modify an existing group.

Delete: Remove a group from the Logical group list. Click Delete, then the group you wish to remove.

Position: Change the order in which the groups are displayed. Click Position, then the point you wish to move. A red bar will accompany the cursor. Click when the red bar is where you want the group to be positioned.

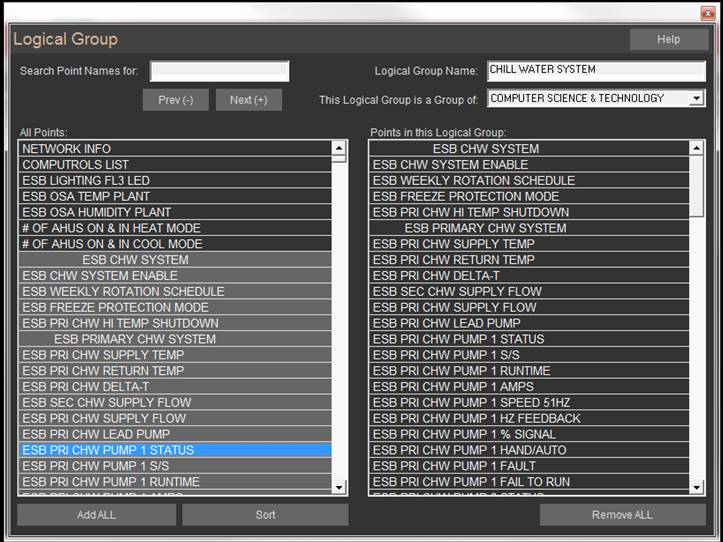

See the Logical Group Editing screen below:

Search Point Names For: Easily Search through the All Points list by typing in any portion of the point name you would like to add to the logic group.

To search down the list, press (+) or click Next (+). To search back up the list, press (-) or click Prev (-).

Logical Group Name: In the top right corner of the Logical Group Editing screen, you can name the group. We recommend naming it based on the common attribute that the points in the group share.

This Logical Group is a Group of: Make your new group a subgroup of either the Logical Group Main Menu or your choice of existing groups. Whatever group you select here will have a drop-down menu that includes your new group.

![]()

The following example should make this clear:

Where New Logical Group is a sub-group of FREE COOLING, a sub-group of the Logical Groups Main Menu.

![]()

All Points: From the list on the left side, click the points you would like to add to the group. To remove from the group, click the points again. In the example screen, the three shaded groups are selected.

Points in this Logical Group: Lists the points in the logical group you are editing.

Add All: Allows you to add all points from the left window to the logical group.

Sort: Modify the All Points list to choose from. See Advanced Sort below.

Remove All: Clears the Logical Group of all points.

Alarm Summary: Lists all points that are currently in alarm.

Lost Communications: Lists all points in the database currently with a lost status.

Unit Summary: Lists all points that share the same units of measurement. When you click Units Summary, you can choose from Analog or Binary units. Then select the units by which the points you would like to view are measured.

Binary Status Summary: The submenu of this item allows you to view all points with a particular Binary Status, such as ON, Start, Open, etc.

Priority Summary: Lists all possible ways by which a point can be commanded. (Schedule, Logic, etc.) The prioritized command options are listed from lowest to highest. If a point is commanded by two or more different priorities, the highest priority will command the point. Click on a menu item to see a list of all points being commanded by that particular priority.

Program Summary: Lists all points that share the same Programming options from the Point Program screen. For example, all points with alarms can be viewed by clicking on the Alarm submenu item.

Disabled Summary: Submenu items list all points that share the same Programming options from the Point Program screen when those programs are disabled.

Attributes: A way of commanding groups of points to the same value. Covered in the Advanced Programming section.

Activity: Developed for showing live Access Control activity, like cards used and door alarms. Can also be configured to show other types of alarms and activity by going to System, Configure Workstation, Activity View Setup.

Advanced Sort: This window appears when you click the Sort button. It allows you to narrow a search based on specific sort criteria.

There are some other tools for organizing and grouping points.

F3: In Text View, you can add bold lines between points by highlighting a point and pressing the F3 function key. This will add a bold line above the point. Press F3 again to remove the line. This feature is good for creating groupings of related points.

F4: You can bold the name of a particular point by highlighting it and pressing F4. Press F4 again to return to normal font.

Search: At any time, you can search for a point by typing the name or a portion of it and pressing the (+) key to search down the list, and the (-) key to search back up the list. Starting in CBAS 15.2, there is a Filter button that, when clicked, shows you only the points with names that contain what you typed.

In the top left of All Points is a search field and some buttons:

![]()

Just type part of the name of the point or points you are looking for, then click one of the buttons to the right.

+ takes you down the list and finds the first example.

- takes you back up the list.

Fltr gives you all examples of the string in its own list.

* deletes what you have typed in the field. Otherwise you can back space.

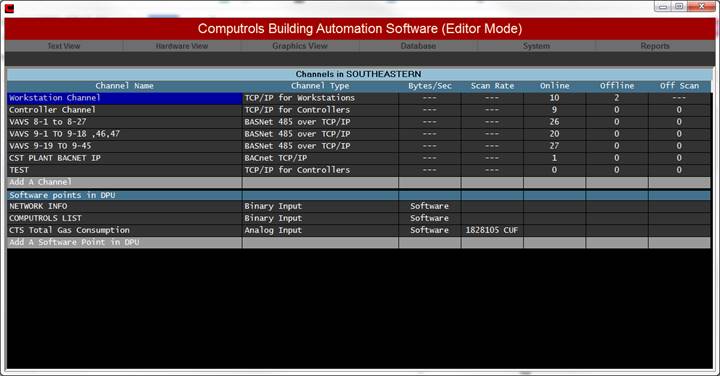

Hardware View uses an expandable tree diagram to represent the automation hardware of the system. Unlike the Text View, this starts from the DPU to the channels, to the controllers, to the points. To expand a tree, click the channel name:

Hardware View is a way of looking at the database logically or topographically. First, you see the channels connected to the computer. As you go deeper, you see the controllers connected to each channel. By looking into the controllers, you see the points. Any Channel, Controller, or Point can be completely configured in Hardware View.

Below the Channels, you can see a list of Points added to the “DPU”. In other words, they are Points that do not reside in a Controller, but stay in the CBAS Database on the server running CBAS. Some Points cannot be added to Controllers, like System Points, and others are just best not being in the Controller.

When you click on Hardware View, the first view you see is a list of channels. At the top of the channel list you will see “List of Channels in (Database Name).” Each line lists the channel name, channel type and lists how many controllers are online, offline, and off scan. Some communication statistics are also shown. See the previous figure.

The first channel listed is “TCP/IP for Workstations” channel, which contains a list of Graphic Workstations (GW) which share the database on the DPU. This channel is actually the same channel as the TCP/IP Channel containing controllers, but is provided as a convenience to separate controllers from workstations.

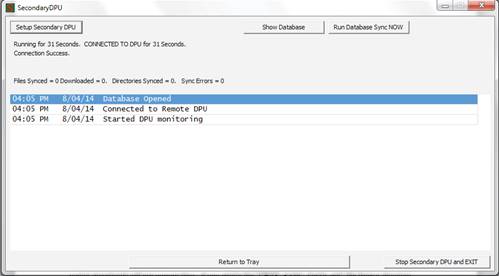

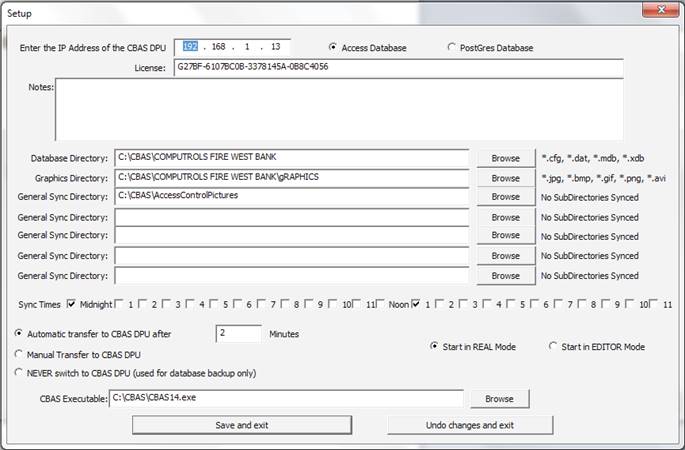

If you click on this channel and click Program, you will see the IP Address of the Channel. This is actually the IP Address of the network card in the computer and is configured automatically when the database is created. If the IP Address needs to be changed, it can be changed here. In later versions, there are places for 2 IP addresses. The second IP would be for a Secondary DPU, which is a redundancy feature that will be covered in Advanced Programming.

There are other things on the Workstation Channel, such as:

String Servers which allow CBASweb to connect and share the CBAS Database. In Editor Mode you will see 12 String Servers because one is required for each time someone connects to CBASweb. You will only see one in Real Mode.

VAV-B Commission is the link between CBAS and the VAV-B Utility program when you click a VAV-B in Hardware View.

Critical Alarm Terminal is a special type of GW that works with the Critical Alarm feature to make sure that engineers are addressing Alarms.

DDCC give CBAS a connection to the program that applies firmware changes to X and LX controllers.

GW Secure and Cloud Interface are features that will be included in future versions.

If you click on the TCP/IP for Workstations Channel and click Controllers, you will see the list of Workstations. You will notice that Local GW is always online because it is the Graphical Interface of the DPU, not a Remote Workstation. A new Workstation can be added here by clicking the last line, Add a GW/ String Server. Right click or press ESC to return to Channel View.

BASnet TCP/IP, BASnet RS-485 over TCP/IP, BASnet, and Opto channels are listed in Channel View and can be added by clicking on the bottom line of the list, Add a Channel. To learn how to create channels see the Channels section.

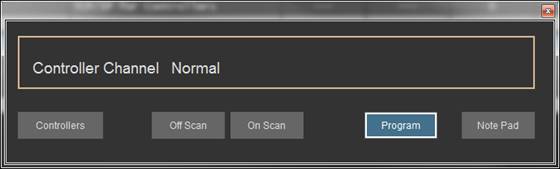

Click the Channel then Controllers to see the Controllers programmed on the Channel. Clicking a Channel will also bring up a window that allows you to take the entire channel Off Scan, put it On Scan, and Program the channel. Off Scan disables communications with all of the controllers on the channel. On Scan enables communications with the controllers on the channel.

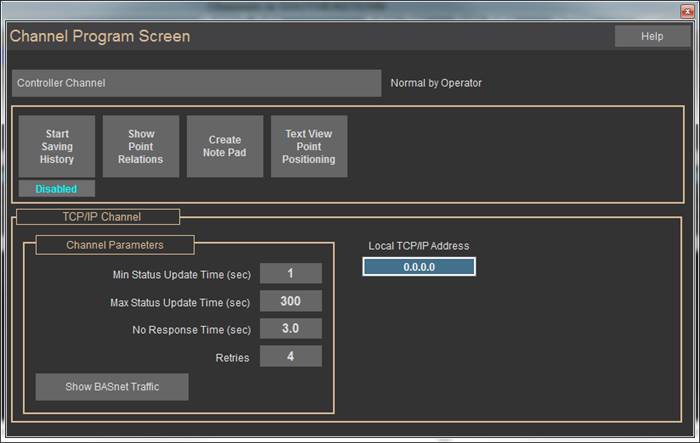

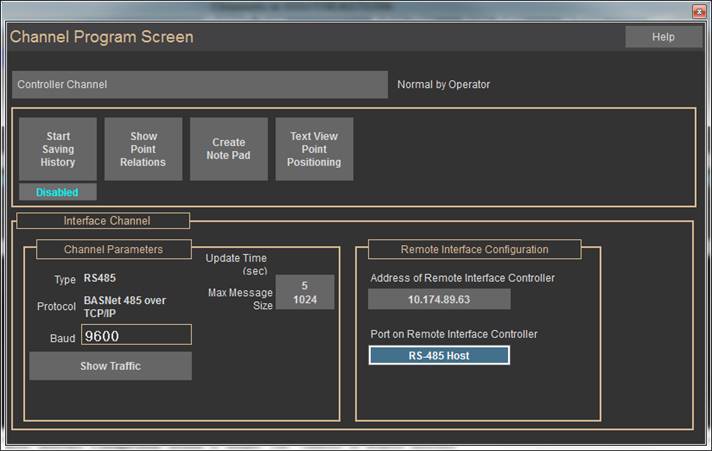

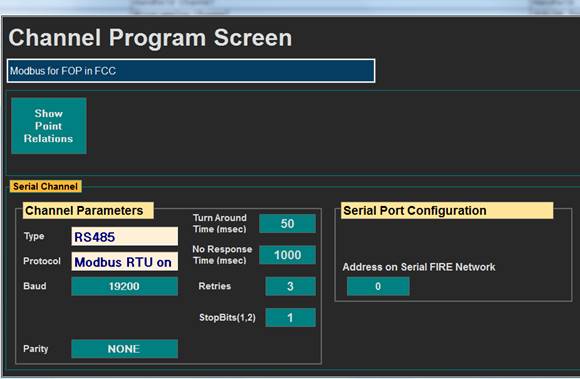

When you click on the Program button, you will see the Channel Program Screen below, which is an example of a Channel Program screen for a BASnet TCP/IP channel:

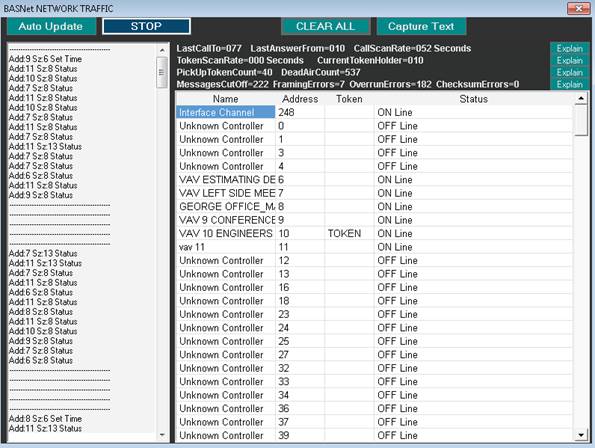

Here, you can view or change the IP Address and other parameters of the channel. It is recommended that the default parameters not be changed unless recommended by Computrols Technical Support. By clicking Show BASnet Traffic, you can view information about the packets going back and forth on the channel when in Real Mode. By clicking on the name of the Channel, in this case IP Test Channel, you can change the name of the channel.

![]()

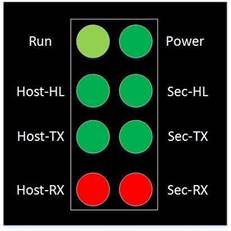

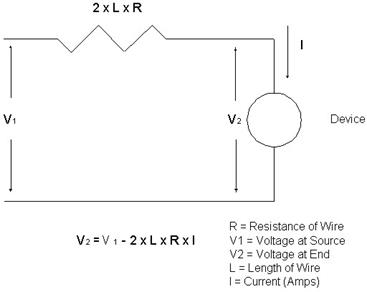

From the Channel Program screen, click a BASnet RS-485 over TCP/IP channel, then the Program button to bring up the window below. This type of channel uses RS-485 communication on a channel hosted by a controller residing on a TCP/IP Channel. A TCP/IP controller can host two of these channels using the Host Channel and the Secondary Channel.

You can do many of the same things on this type of channel that you can do on the TCP/IP Channel; however, the Remote Interface Configuration section is unique. The “Address of Remote Interface Controller” is the actual IP Address of the controller that is hosting the channel. The “Port of Remote Interface Controller” can be either RS-485 Host or RS-485 Secondary.

To learn how to create channels go to: Channels

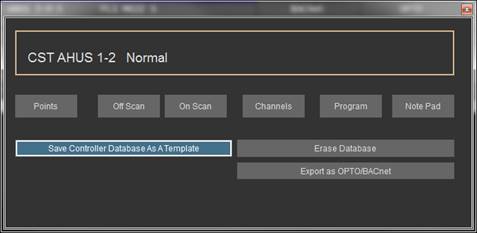

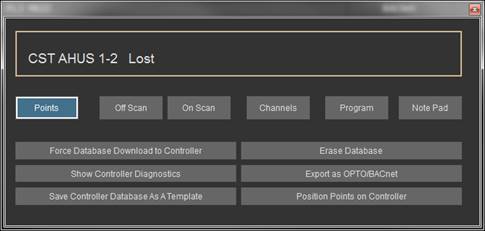

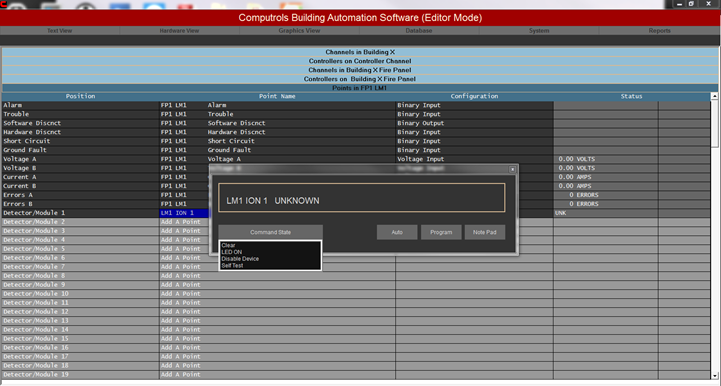

To view controllers on a particular channel, click the channel and then click Controllers. You will see a list that shows the address, controller type, controller name, and communication status. Communication status will either be Lost (Yellow), Normal (Blue), Scan Off (Gray), and Alarm (Red) when viewing in Classic Color Theme. When viewing the new Dark Color Theme, then colors will be Lost (Yellow), Normal (Dark Gray), Scan Off (Yellow), and Alarm (Red). Click on a controller to see the following window:

From here you can take the controller off scan and put it back on scan. From the Channels button, you can view the channels on the controller and add RS-485 channels. If you are planning on adding other controllers with the same points, you can Save Controller as a Template. Templates are fully explained in Chapter 3, Section 3, Templates.

Click Note Pad if you want to write down some information about this particular controller. In Real Mode, you will see a few more choices. See below:

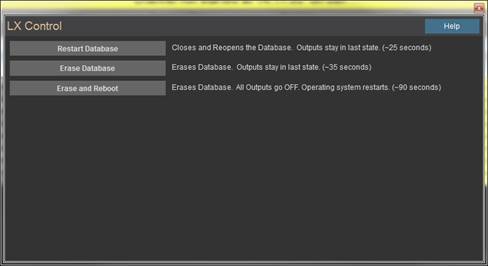

When changes are made to a controller’s database, the new database should download to it automatically. If you have made changes to a controller’s database and you are not sure if it has downloaded to the controller, you can click “Force Database Download to Controller.” “Erase Database” will do the same thing, because a controller with no database will always download automatically. However, when you select the erase the database on the controller, it will give you three options from which to choose.

Click “Show Controller Diagnostics” to see a screen listing diagnostic information on the controller.

Controller Diagnostics can be a useful tool for troubleshooting problems with the following controllers: 8X, 16X, 32X, 64X, 8LX, 16LX, 32LX, 64LX, VAV-B, UNI-B and VAVs. This feature will be explained further in the Troubleshooting chapter.

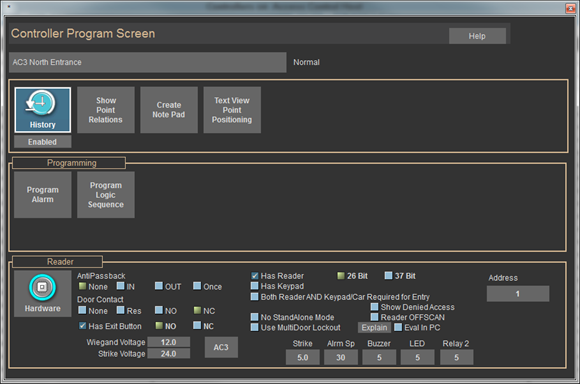

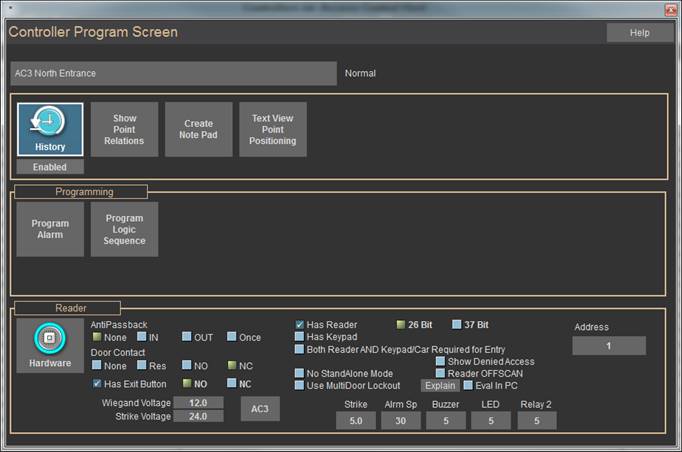

Click the Program button to get the following window:

From the Controller Program Screen, you can change the name of the Controller, change the address, view some information about the controller, and setup an Alarm that will go off if communication to the controller is lost.

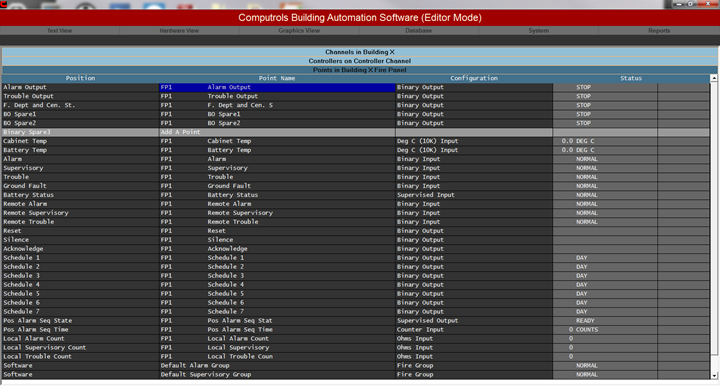

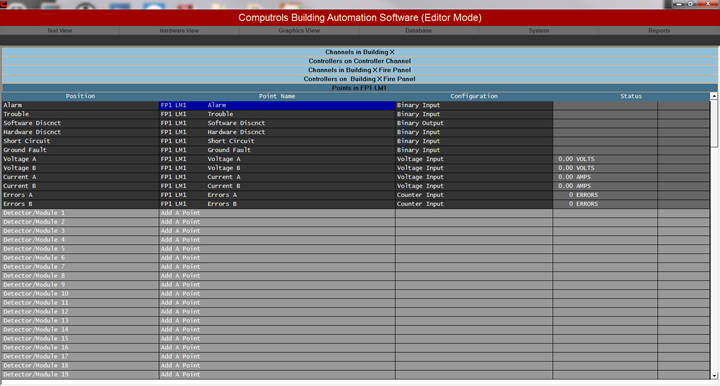

To view the Points on a particular Controller, Click the Controller then click Points. The points are listed in order of physical position on the controller, with Software points below Hardware points.

Each point listing shows the position, point name, configuration, and status. The Status column shows the current value in units specified in configuration, as well as how the point was commanded, also known as Priority. Priorities include “OPER” for Operator, “HH” for Handheld, “SCHED” for Schedule, “PID” for PID and “LOG1” for Logic. (There are 4 levels of Logic that can command a point) Click a Binary Output point to see the following window:

The window shows the point name and status. Click Stop to turn off and Start to turn on. The Status column in Points View will show Stop and OPER if you click STOP. Click Auto and the point can be commanded either by Logic, Schedule, PID, etc., depending on how it is programmed. The Status column will then reflect how it was commanded.

Click the Program button to see the following window:

In the above example, the point may be commanded by either Schedule or Logic. For information on the Point Programming Screen, go to Chapter 4 Programming Points.

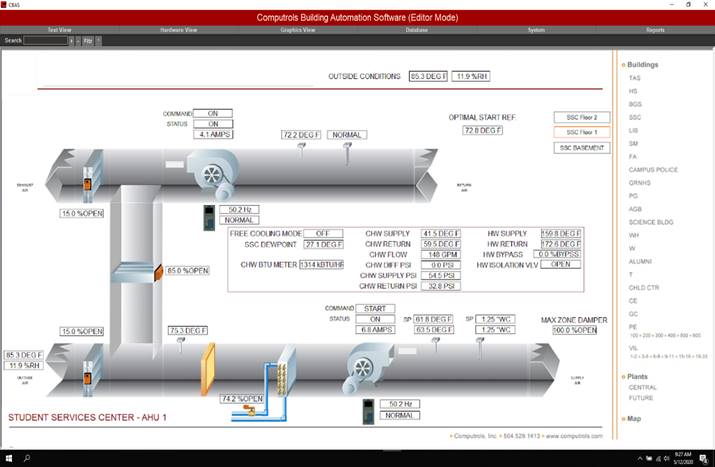

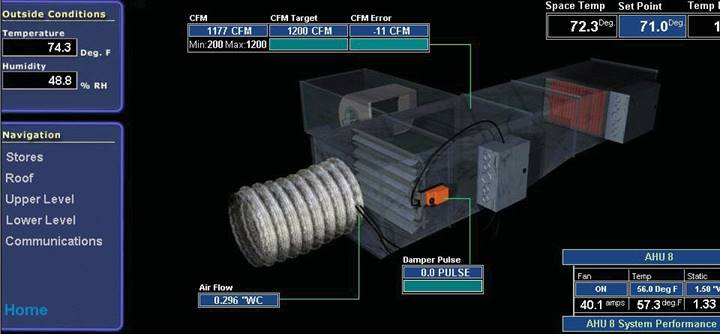

This view depicts a graphical representation of your building’s equipment. From this view, you can navigate from a floor to the equipment on the floor, to the controllers, and eventually to individual points. Below is an example of a VAV controller.

Using the Graphics View presents an infinite array of possibilities for both navigating and displaying any building’s database. With the aid of the built-in CBAS Graphics Editor, any user can easily create a thorough yet simple-to-use graphical user interface (GUI). The graphics editor allows you to import graphic files (BMP or JPG) to use as backgrounds. Over these backgrounds can be displayed any of a number of different attributes of any point in the system’s database. The editor offers most of the features found in today’s more popular object-oriented editing software. Menu items such as global edit objects, layering and “hot keys” make editing your graphics in CBAS simple from the start.

Main: Before any graphics have been programmed, the system will default to a blank graphic titled Main. The name assigned to the first graphic created will then replace the title “Main.” Usually this first graphic is used as the Graphics View home page. As you will read later, graphics can be repositioned allowing you to make any graphic the first or Main graphic.

Select Graphic: This option allows you to select from and view each of the graphics in the current database whose “Hidden” checkbox has not been checked. If no graphics have yet been added to the current database, the Select Graphic sub-menu will be empty. If there have been graphics created for the database, the Select Graphic sub-menu will list those graphics in the order in which they were created, unless otherwise re-ordered through Position Graphics described in Chapter 3, Section 5.

In order to select a graphic from the list, simply click its name. The selected graphic will then be displayed in the active view area.

Each CBAS software installation comes with a Graphics Library, which is provided for your convenience and can be accessed through Windows Explorer. The 3-D VAV in the previous graphic is an example of what is in the Graphics Library. Pictures are sorted into folders by type, such as Air Handling units, VAVs, Central Plant. These pictures can be used as backgrounds for graphics pages in your database, and cover most types of equipment in use today. They can be changed using any graphics program. Custom graphics can also be obtained from Computrols for a fee.

To access the Graphics Library from Windows Explorer, go to C:\ CBAS\ Graphics Library. The first time you access this folder the contents will have to be unzipped by clicking on GraphicsLibrarySetup.exe

At any time while in Graphics View, you can enter Program Graphics Mode by pressing CTRL+E. Programming Graphics is covered in Chapter 3, Section 5, Program Graphics.

Below is an example of an RTU created in Microsoft Visio using the “shapes” developed by Computrols. Dealers can obtain these shape stencils and create their own 3-D graphic representations of AHU schematics and central plant piping.

![]() Chapter 3 » Programming

Databases

Chapter 3 » Programming

Databases

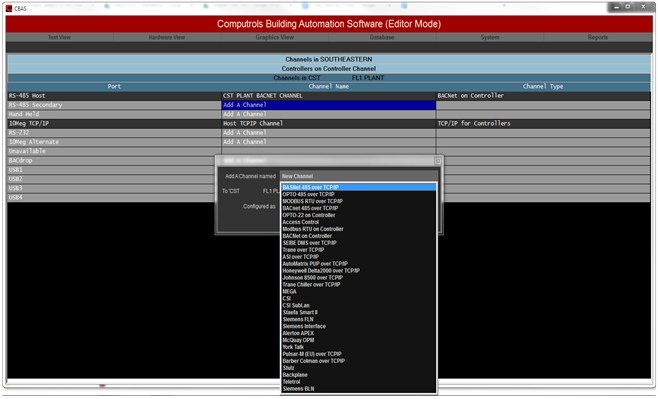

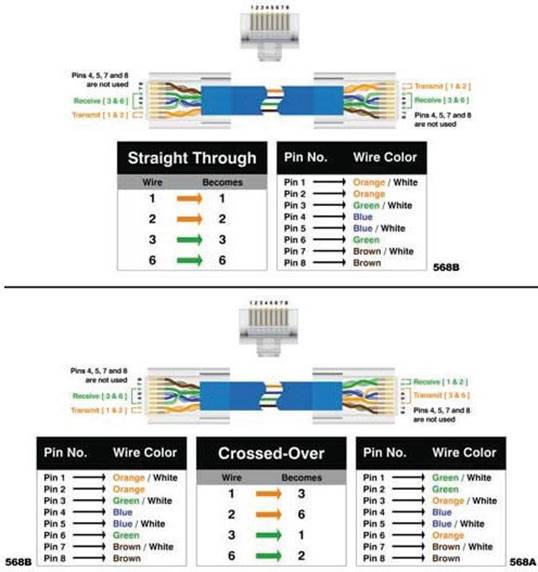

A Channel is the communication link between the controller and the head-end PC or DPU. They are often called “trunks” in the building automation industry. A Cat-5 cable is connected from a Network Card or twisted pair is connected from a “Host Controller”. Generally, only one Network Card and TCP/IP Channel will be needed for TCP/IP controllers, as each channel can host up to 252 controllers. To add more than 252 IP Controllers, add a second channel. For instructions on how to configure networking in Windows to facilitate 2 TCP/IP Channels, call Computrols Technical Support.

![]()

To add a channel from Hardware View:

· From Channel View, click the last line, “Add a Channel”.

· In the dialogue box that appears, click on the Channel name field and type a name for the channel. The name should be descriptive of the location of the controller hosting the channel, similar to the image below. It can be up to 32 characters long.

· Hit Enter and select a configuration from the following list:

· BASnet TCP/IP for Computrols controllers

· BACnet TCP/IP for 3rd Party BACnet controllers

· BACnet IP Router for connecting to BACnet Routers that bridge to other protocols

· Modbus TCP/IP to 3rd Party Meters mainly

· Simple Network Management Protocol to datacenter PDU, UPS mainly

· Thyssenkrupp elevator destination system

· Mitsubishi elevator destination system

· Hit Enter and Enter again or click the “Add Channel Now!” button.

In order to add a BASnet RS-485 over TCP/IP channel, you must first add a host controller to the TCP/IP Channel. Each controller on the TCP/IP for Controllers Channel can host 2 RS-485 channels. See the next section for instructions to add a controller. Once you have added the controller that will host the BASnet RS-485 channel, follow the steps below:

· In Hardware View, go to the TCP/IP for Controllers Channel and locate the controller that will host the RS-485 channel.

· Click the controller and click Channels. Refer to the figure below.

· Click “Add a Channel” on either the RS-485 Host or RS-485 Secondary line.

· Give the new channel a name that describes its location.

· Under Select Configuration, choose BASnet RS-485 over TCP/IP. Notice that there are many choices here. The others are interfaces to other manufacturers’ equipment, which require an add-on license to be purchased.

· Click “Add Point Now!”

· Press ESC and you will now see the channel listed in Channel View.

BACnet TCP/IP for 3rd Party BACnet controllers

BACnet IP Router for connecting to BACnet Routers that bridge to other protocols

Modbus TCP/IP to 3rd Party meters mainly

Simple Network Management Protocol to datacenter PDU, UPS mainly Thyssenkrupp elevator destination system

As you can see above, there are many different RS485 channel types available in CBAS which are mostly “interface” channels that just pass data back and forth to the DPU. The channel types with “on Controller” contain the child controller points in the Host Controller’s database and the Host acts as a DPU itself.

![]()

![]()

· From the Main menu, click Database and click Remove a Channel.

o Or, if you are removing an “On Controller” channel, choose Remove a Channel On A Controller.

· From the list that appears, select the channel you want to delete.

o When removing a Channel On A Controller, you must first choose the TCP/IP for Controllers channel, then the controller that hosts the channel.

· Host Controllers can contain 2 Channels, so select the one you want to remove.

· You will be asked twice if you are sure you want to delete the channel. If you are sure, answer Yes. You will no longer see the channel in Hardware view.

![]()

![]()

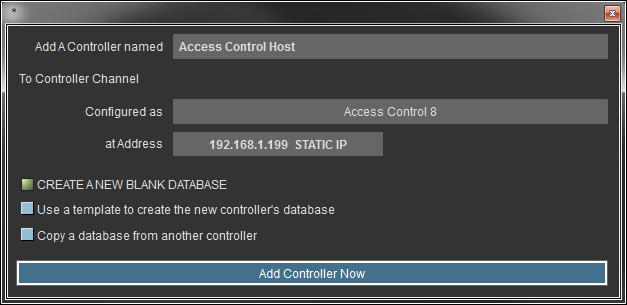

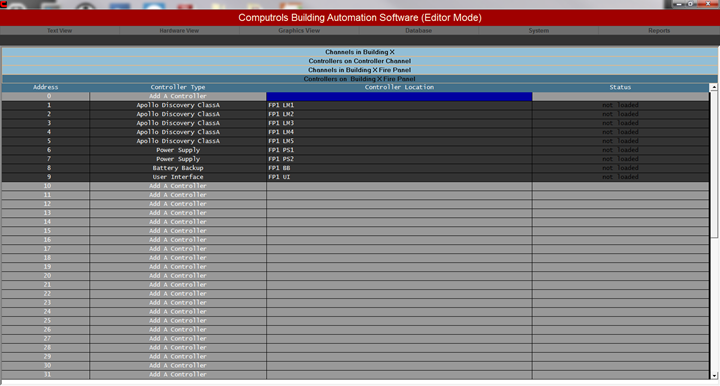

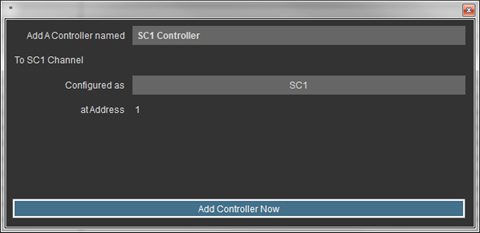

To add a controller from Hardware View:

· From the Channel View screen, click the channel you wish to add the controller to, then click Controllers.

· Click on the bottom line, “Add a BASnet Controller.”

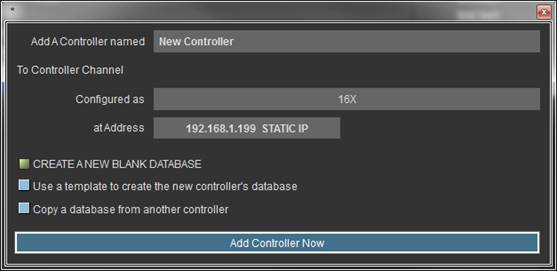

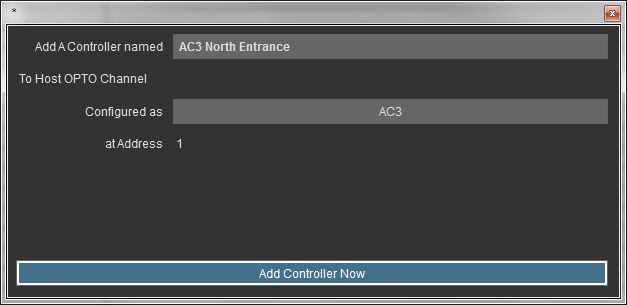

The following screen will appear. This is an example of adding a controller on a BASnet TCP/IP channel.

· Enter a name for the controller and hit Enter.

· Select a Controller type and hit Enter. Put in an IP Address that will work on the channel. Select CREATE A NEW BLANK DATABASE, USE A TEMPLATE… DATABASE or COPY A DATABASE FROM ANOTHER CONTROLLER. If using a template, you must create a template from the same controller type and the same version of CBAS. For more information on templates, go to the Templates section.

· Click Add Controller NOW!

If you choose to add from template, you will be sent to the Templates folder to select the Template. If you choose to copy, you will be sent to select a controller from the other controllers in the current database.

To add a wider range of controllers, add them from the Database menu. However, the preferred method of adding controllers is through Hardware View.

· From the Database menu, left-click Add a Controller.

· Type in the name and click Next >. The name can contain up to 32 characters and must be unique throughout the database.

· Left-click the Make and Model. Make is the communication language of the channel. Model is the type of control board. For each Make, there are different choices of Models. Click Next >.

· Left-click the database if you have more than one in which you want the controller to reside. Click Next >.

· Left-click one of the existing communication channels to which the controller is connected. Click Next >.

· Left click an open address on the Channel. A channel can have up to 247 controllers, but we recommend adding up to 80 for quicker communication. Each controller takes time to communicate through the channel, so the fewer you have, the more rapid the communication. We recommend selecting the address so that you can easily remember later on. For example, a DDC on the 22nd floor could be addressed 22. Click Next >.

· Choose either a blank database, or from a list of Pre-Programmed Templates. If you choose a blank database, you have added the controller and are ready to begin adding points. If you choose Preprogrammed templates, continue.

· Choose a template. See the Templates section below.

![]()

· From the Main menu, click on Database and click Remove a Controller.

· From the list that appears, select the channel that contains the controller you want to delete. From the list that appears, select the controller that you want to delete. You will be asked twice if you are sure you want to delete the channel. If you are sure, answer Yes.

You will no longer see the controller or its associated points in Hardware view.

A template is a duplicate of any Computrols BASnet controller and all its points, logic, schedules etc. It is used in order to save time when programming multiple controllers used for the same function. For example, if 20 AHUs in a building are controlled by 20 32Xs with the same points for each, you can create a template with the first 32X you program and then select that template for the other 19.

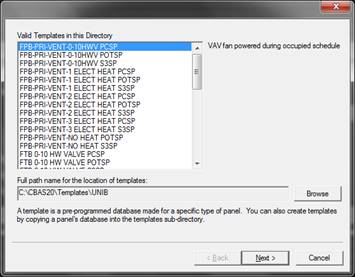

CBAS 20 already has many templates for the UNI-B controller, which uses the BASnet protocol. They are located in CBAS20\Templates\UNIB folder are named based on the different VAV application that are possible and each type also has 3 varieties depending on the temp sensor and setpoint types. Example: FTB 0-10 HW VALVE S3SP means Fan Terminal Box with 0-10V HW Valve and MN-S3 Setpoint and Temp.

You can also get templates for the larger IP Controllers and many different AHU types by opening the Template Database. Contact Computrols Tech support at Techsupport@computrols.com and let them know what CBAS version you and that you would like a backup of the Template Database. In CBAS 20 you will take that backup and Install the database, covered previously. Making a Template is covered later in this section.

OPTO, BACnet and Modbus controllers cannot be saved as templates, but can be Exported and the Export file can be used when adding another of the same type. To do so, go to the Database Menu, and then click Copy a Controller. Follow the prompts. Or you can do an Export and Import. To do so, click an OPTO controller, for example, then click Export Database. Then, when you add a new controller of the same type, it will ask if you want to Import the Points. You then select an export file and you will be given the opportunity to change the point names, as discussed later in this section.

To select a template:

· First, add a controller.

· In the next step, click USE A TEMPLATE TO CREATE THE NEW CONTROLLERS DATABASE. The window below will open. All Templates of the controller type you are adding will be listed.

CBAS automatically finds templates in C:\CBAS\Templates\[controller type] folder. However, you can click the Browse button and browse to the Template Database folder, and CBAS will find all eligible templates. (you must have a template created in the same CBAS version)

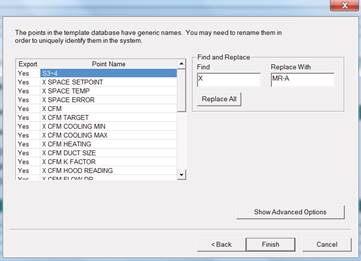

· Click a Template from the list. The window below will open:

Anything you type in the “Find” box will be changed to whatever you type in the “Replace With” box when you click “Replace All”.

· Click “Show Advanced Options”.

· Click “Replace” to replace the selected point highlighted in blue. What you type in the Prefix box will be the first characters in the name and what you type in the Suffix box will fall after the name.

· Click “Finish.”

Add to Name: Adds the prefix and suffix to the selected point.

Add to All: Adds the prefix and suffix to all the points in the list.

Manually Replace Name: Fill in the box to the left of this button. When you click this button, the highlighted point’s name will change to what you typed in the box.

From the Hardware view, click the channel that the controller is on and find the controller you wish to use as a template. When you click the controller name, the screen below will open:

Click here to save all the programming and parameters of this controller to a template. This is useful if your facility has the same automation needs for different floors or areas of the facility. When you left-click here, CBAS prompts you to create notes in the Note Pad relating to this template and then asks you to give the template a name. When you add a controller to your system that will be programmed and wired similarly to the one you are saving as a template, the task will be simpler.

When CBAS is first installed, no site-specific data is programmed into the system. Each database is unique to the individual site. Whether you are installing it yourself, or having Computrols or one of our licensed dealers install CBAS, it is helpful to continue reading to familiarize yourself with the system setup.

Engineering the project is the first step. Specific information about the facility is needed before programming can begin. Blueprints including locations of all mechanical equipment, specifications,

as-built drawings from any existing system, and any specific instruction must be made available to the project manager. If you are upgrading an existing automation system, most necessary information can be obtained from reports and printouts for the existing control equipment. For new installations,

a Computrols design Engineer, or your own project manager should provide all specifications. Once you have the project planned out, you can begin entering data into CBAS.

All field devices and any logic or calculations associated with those devices are points. A point can be an actuator, a temperature sensor, a control sequence or any other quantity or status that can be monitored or controlled. We recommend naming your points based on their location and function to make it easier for the operator. For example, if you have a temperature sensor that reads the space that AHU-2 serves, name the point “AHU-2 Space Temp.” There are two categories of points: Hardware and Software.

Hardware points are devices that can be physically wired to the terminal strip of a controller. They include field devices such as relays, actuators, and sensors. Their function is to transmit data back to the controller or physically carry through a CBAS command.

There are four main types of hardware points. They are analog inputs, analog outputs, binary inputs, and binary outputs. Binary points have only two states such as ON/ OFF, OPEN/ CLOSE, or START/ STOP. Analog points on the other hand, represent a range of measurement such as a temperature of 0°F to 110°F, a pressure of 1psi to 5psi, or a flow rate of 100 “WC to 200 “WC.

Whether a point is Binary or Analog, it must be either an input or an output. Points that monitor the status of a field device are inputs. Field devices send their condition or quantity to an input on the controller.

Points that control the status of a field device are outputs. The user can either control outputs manually, or allow for automatic control based on schedule, logic, PID, or other software outputs programmed in CBAS.

|

Point Type |

Input |

Output |

|

Analog |

Pressure Sensor |

Damper Actuator |

|

Binary |

AHU Fan Status ON/OFF |

Relay |

In addition to the four main point types, points can be IN/ OUT, supervised, or counter.

Linked Points: A separate input can be used to verify that a field device responded to an output. When these two points are linked, it becomes one point called a Linked point. For example, a relay that turns an AHU on when contact is made is a binary output. A device in the duct that indicates an increase or decrease in differential pressure in order to verify that the unit turned on when commanded is a binary input. When the relay output and differential pressure input are linked, the operator can command the AHU to start and watch the status change from OFF to ON through a single point. If you setup an alarm on the points, you will know that the AHU started or not.

Supervised Points: Monitors the consistency of a wire. Sends one of a possible three states: Open, Closed, or Trouble. Trouble is how CBAS defines a broken connection between the controller and the point. For example, if a door is normally closed, a binary point would indicate an open or closed door. A supervised point would do the same thing, but would also indicate when the wire connected from the controller to the door monitor has been tampered with.

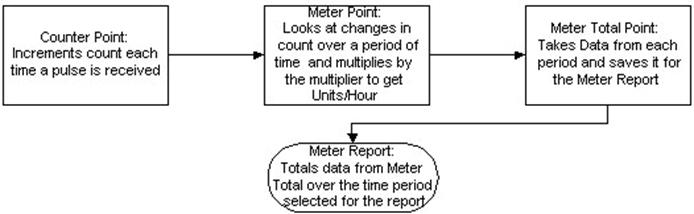

Counter Points: Counts the number of times that a binary point changed status. These are most often used in Kilowatt (KW) meters for monitoring power usage. This number is constantly increasing and rolls over to 0 when it reaches 4,000,000.00.

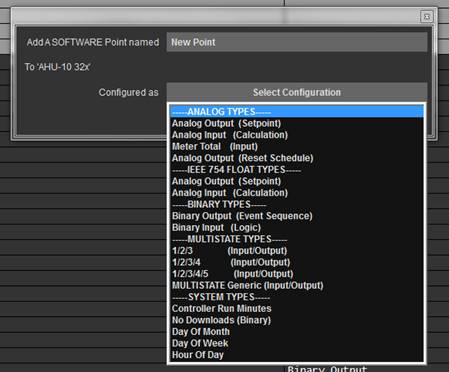

Software points include calculations, points of reference, and logic statements. They are intelligent points that are not physically connected to the controller. Instead, they gather data and send commands to hardware points. An example of gathering data is the average supply temperature of all VAVs on a floor. An example of sending Logic commands is, “if Outside Air Temp is less than 50°F, then start VAV heat strips.” For a complete description of Software Points, see Chapter 4, Section 2 “Software Points.”

Each panel has a given number of hardware points based on the type of controller. The entire database can have up to 60,000 software points. Once a panel is added to the system, there are two ways to add a point: From Database on the Main Menu or from Hardware View. The preferred method is from Hardware View and the Database Menu is used only to add special “System Points”.

![]()

You will be prompted for all of the information necessary to add the points to

the system. Note that CBAS prompts you with only choices that make sense based

on previous choices. Therefore, some steps may not be necessary for certain

point types. The steps involved in adding points from the main menu are as

follows:

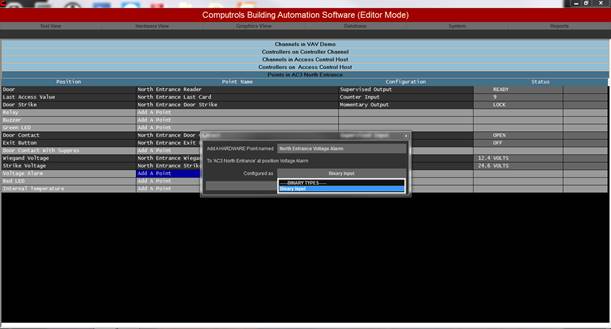

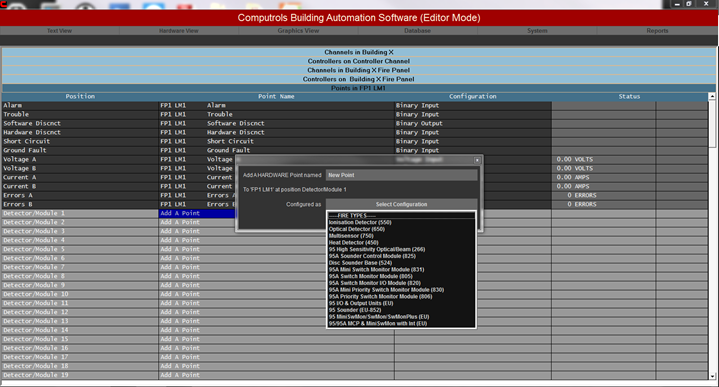

To Add Points:

· Click the channel that contains the controller to which you want to add the points.

· Click the Controllers button and find the controller in the list.

· Click the controller and click the Points button.

· On X Controllers (8X, 16X, 32X, 64X), any point position can be any of the four point types. On VAV Controllers, certain positions are allotted for certain point types, such as Analog, Binary, In, or Out. Software Points are added below the Hardware Points.

· From the list of points, click “Add a Point” on the position where you want to add the point.

· Give the point a unique and descriptive name.

· Choose the Configuration type for the point.

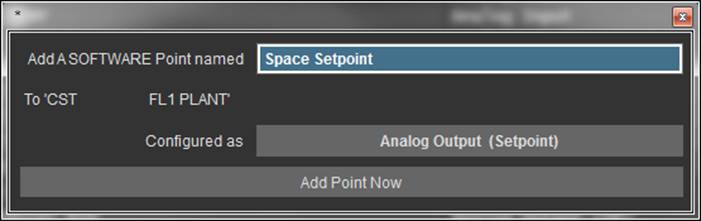

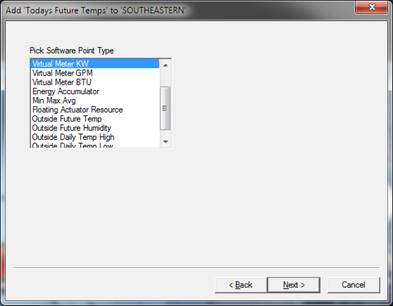

· To add a Software Point, click “Add a Software Point” on the bottom line of the list. The following window will appear:

· Type in a descriptive and unique name for the point. It can contain up to 32 Characters.

· Hit Enter and select a configuration from the drop-down list.

· Hit Enter and Enter again, then click on the Add Point NOW! button.

The process is not complete until you reach the Points Program Screen. If you press ESC or right-click at any time before reaching the Program Screen, the point will not be added.

Once the point has been added, program the point how you wish. If you do not wish to program the point at this time, right-click to return to the main menu. For more information on programming the point after it has been added, go to Chapter 4 Programming Points.

· From the Main menu, click Database and click Remove a Point.

· From the list that appears, select the channel that contains the controller that contains the point you want to delete.

· From the next list that appears, select the controller that contains the point that you want to delete. Select the point and you will be asked twice if you are sure you want to delete the point. If you are sure, answer Yes.

You will no longer see the point in Hardware View or Text View.

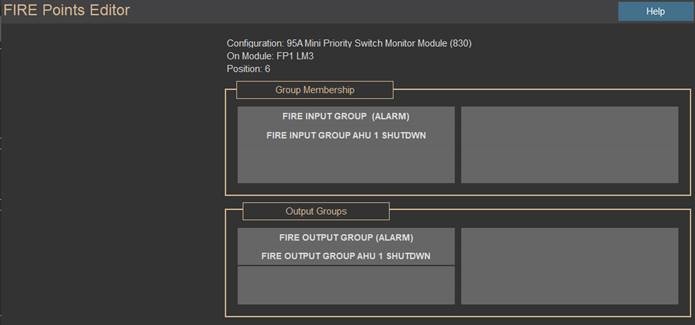

Points are broken down into what we call subsystems, which can work together to provide a complete solution to automation needs. Their title defines the way a point behaves or what its function is. The three subsystems are listed and defined below.

Automation: These points fall under Energy Management. These automated points are the most flexible, and have the most control features available. They are not as application specific as the other sub-systems. Therefore, they require more programming to accomplish what your building requires.

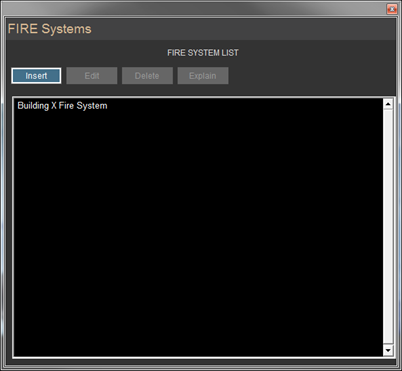

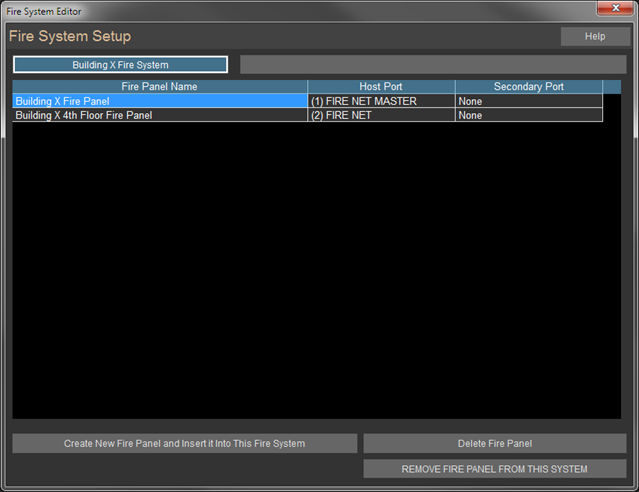

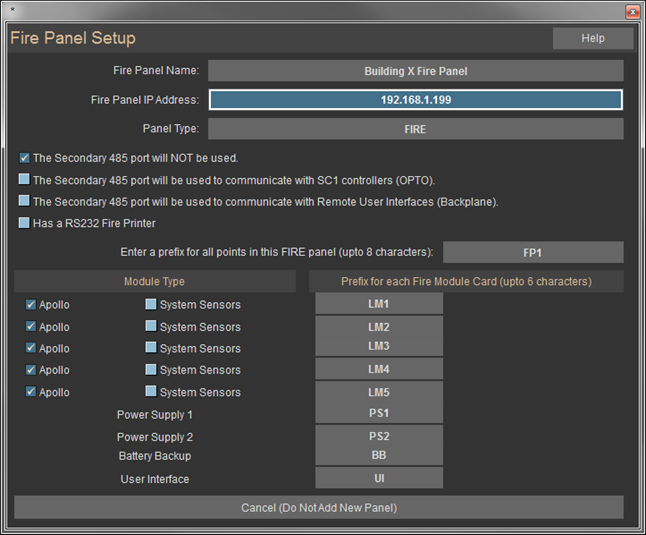

Fire: These points are used in fire detection and prevention. Because the application is more standard than automation, programming is less customizable. This feature requires an add-on to the CBAS license and is a separate purchase.

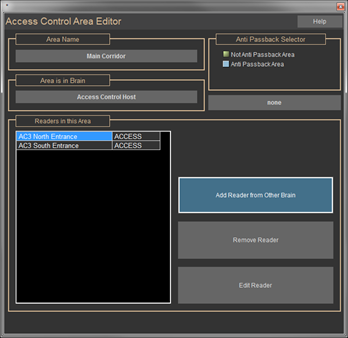

Access Control: This sub-system formerly utilized a separate database to provide controlled access into and out of secured areas of a facility. This feature requires an add-on to the CBAS license and is a separate purchase.

Using subsystems allows for a more organized automation system.

![]() Chapter 4 » Programming Points

Chapter 4 » Programming Points

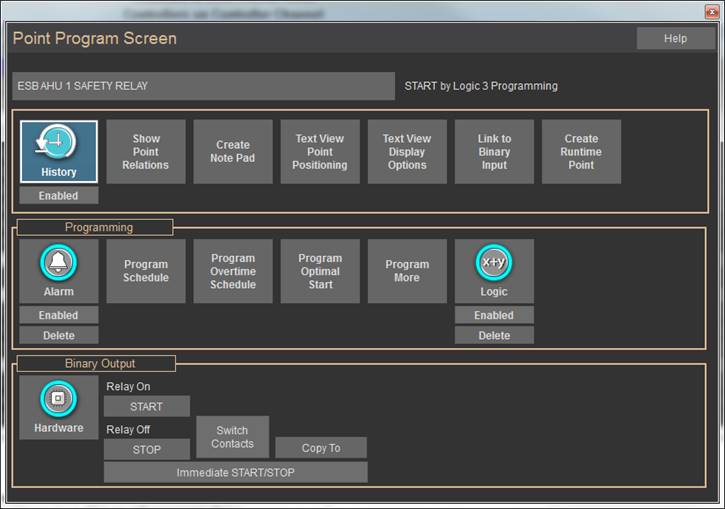

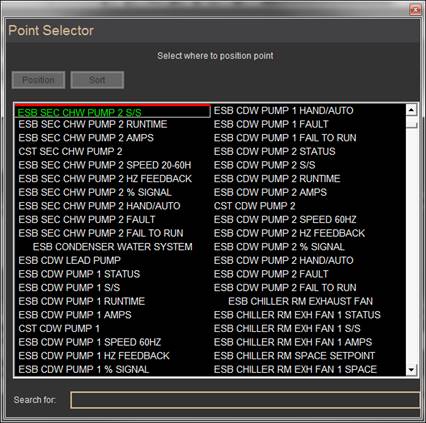

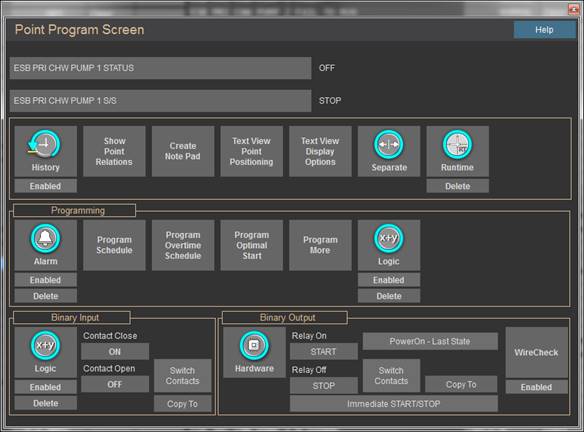

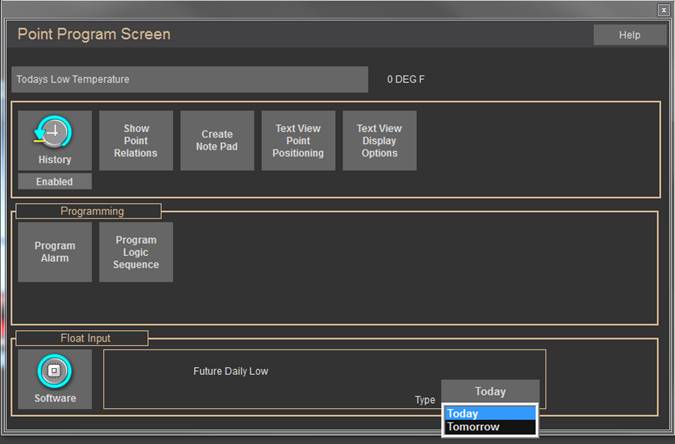

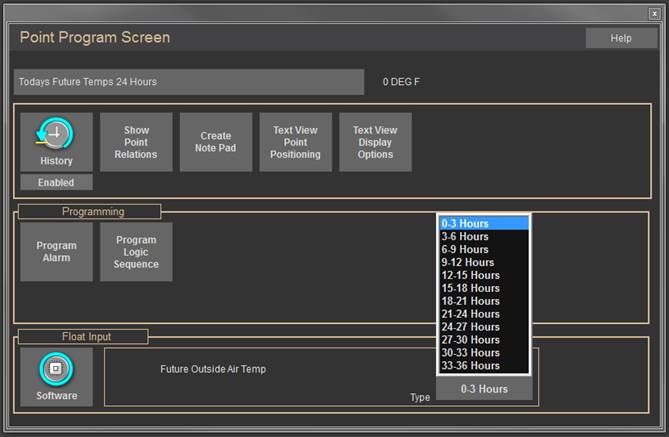

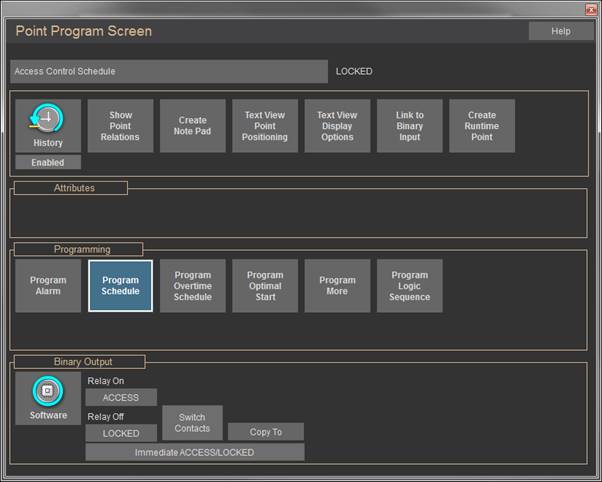

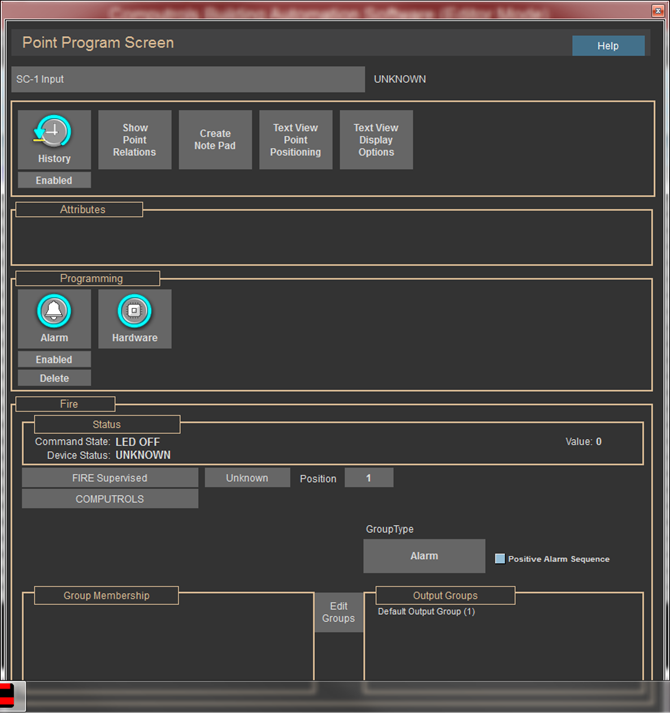

The Point Program Screen shown below allows the user to program a selected point and view its properties. The options displayed vary based on the properties of the selected point. This makes it easier for the user by limiting the choices to only those features that are relevant to that particular point type.

The Point Program Screen is divided into four sections shown here:

Name: To change the name (AUTO POINTS FOR AHU 10 TO 28), click it and type the new name.

Status: Displays the current status of the Point (OFF).

History: CBAS records changes in point status over time based on parameters set by the user. The History function allows you to set the criteria for recording history and view the history of a selected point. If this button is labeled “Start Saving History”, then you might need to enable History saving for the whole database. Do this from History Maintenance on the System Menu.

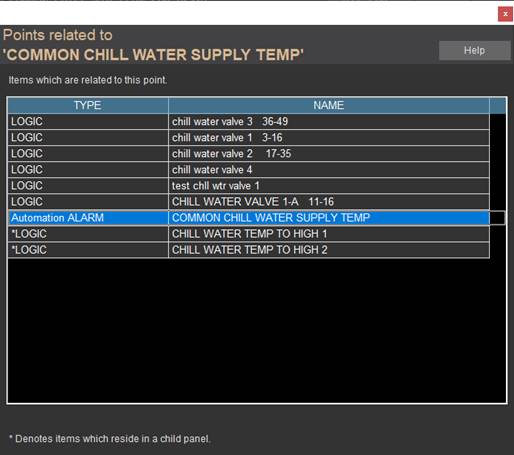

Show Point Relations: Lists all points that are related to the selected point by Logic, PID, etc. You can click on some relations and view how they are setup.

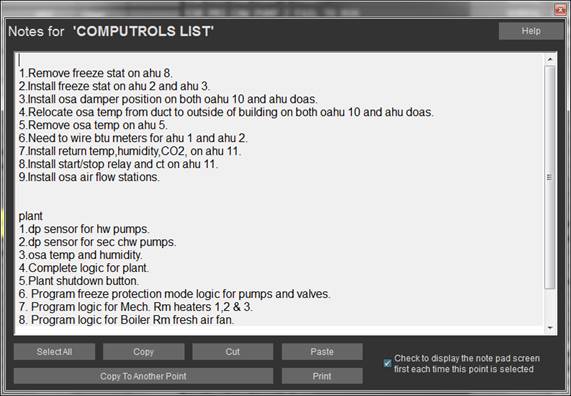

Create Note Pad: Provides a journal for each individual point to record any information about that point.

Text View Point Positioning: Lists all points and allows for changing the order in which they are displayed in the Text View/All Points. When you select this feature, click the position in the list that appears and it is moved there.

Text View Display Options: Helps you organize the layout of the text view. You can place a bar above a point or bold a point. This can also be done with the F3 or F4 keys, respectively. The bars help to group points, and bolding highlights frequently used points.

Link to Binary Input: Allows you to display a Binary Input and Binary Output as one point. Mainly for setting up alarms when status fails to match output.

Create Runtime Point: Creates a point which tracks how long a binary point has been in a specified status.

All programming for an individual point can be done from this section of the Point Programming Screen. Below, each button is displayed and described briefly. Not all of these buttons appear on all point types.

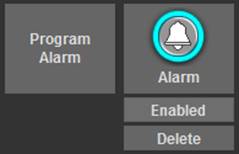

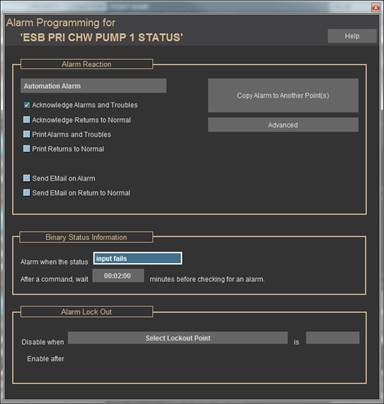

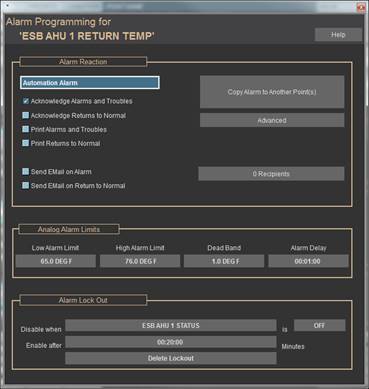

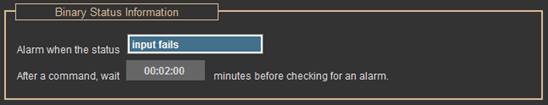

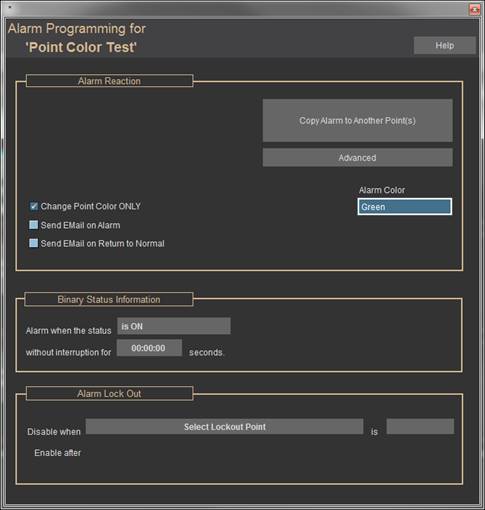

Program Alarm: Program an audio and visual alarm to indicate when a point is functioning differently than you would like.

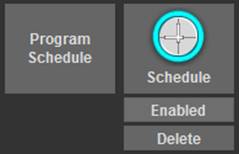

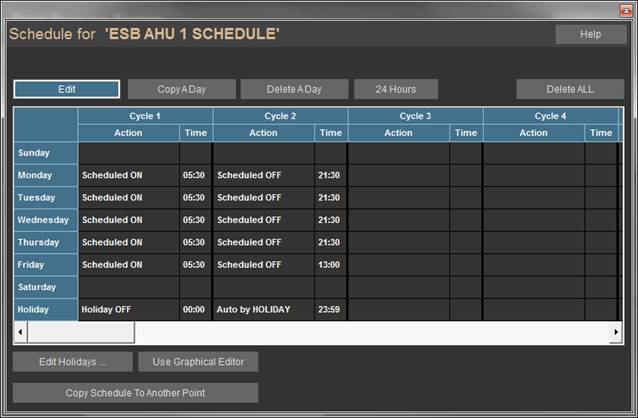

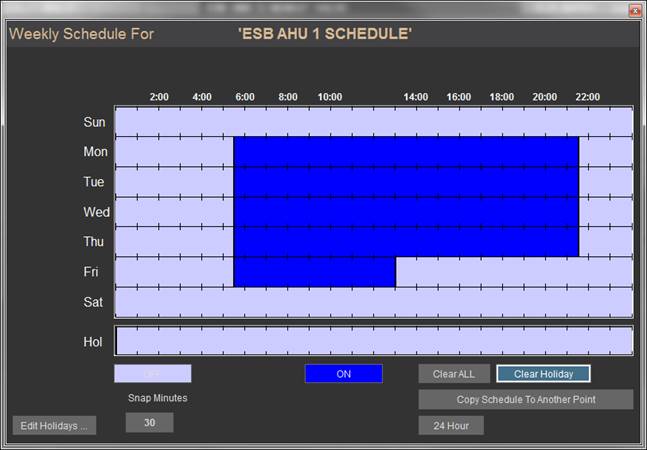

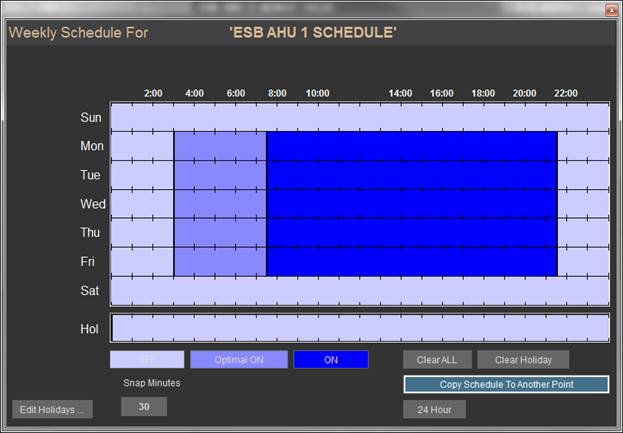

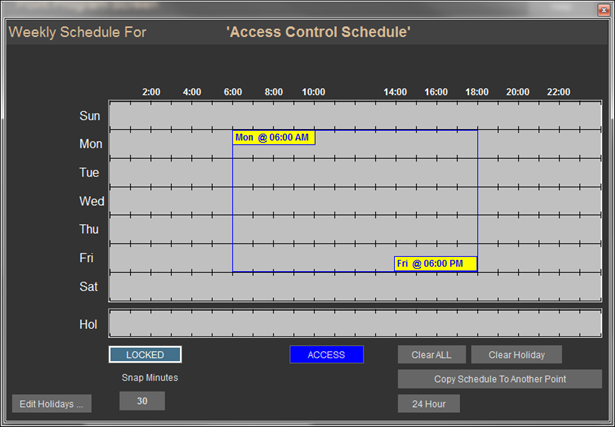

Program Schedule: Program a weekly time schedule for automatically commanding a binary point.

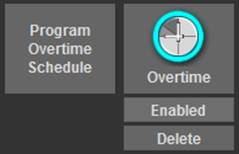

Program Overtime Schedule: Extend or adjust weekly schedules by programming overtime schedules for a specific date.

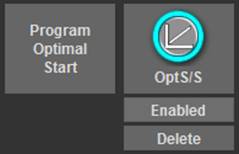

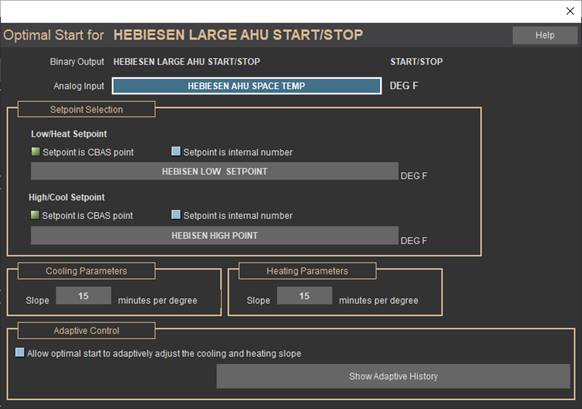

Program Optimal Start/Stop: Program the system so that equipment runs for the least amount of time while maintaining desired conditions.

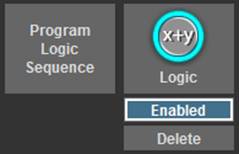

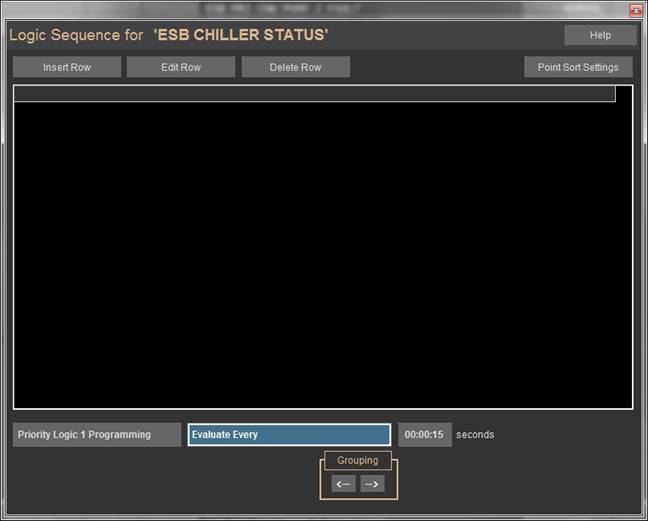

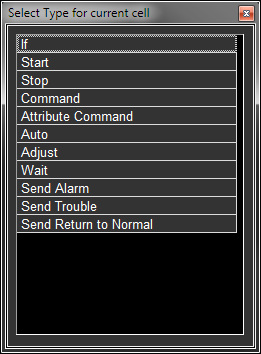

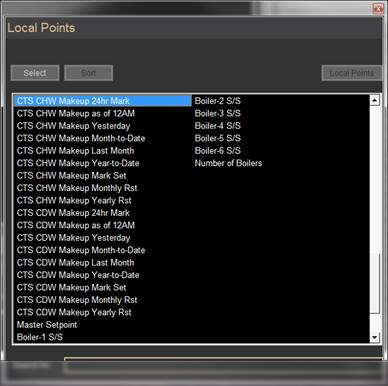

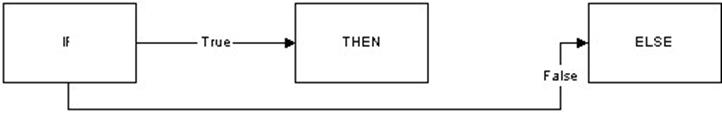

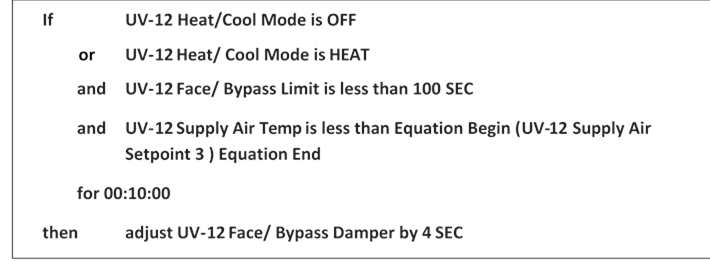

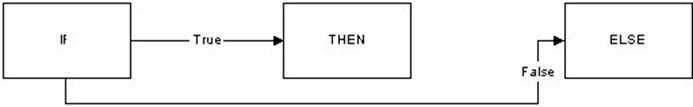

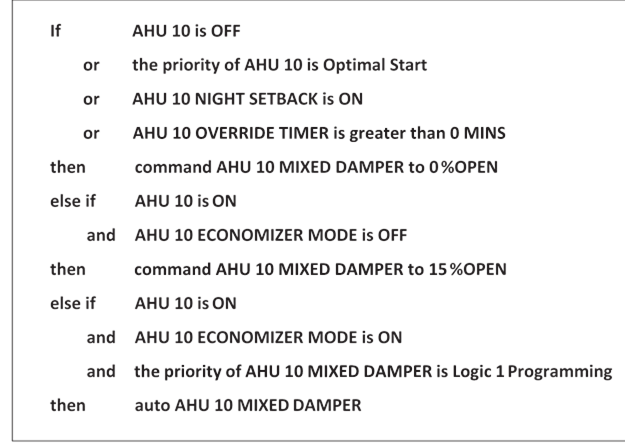

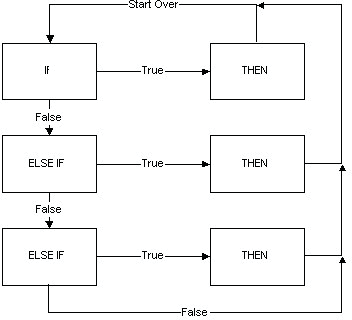

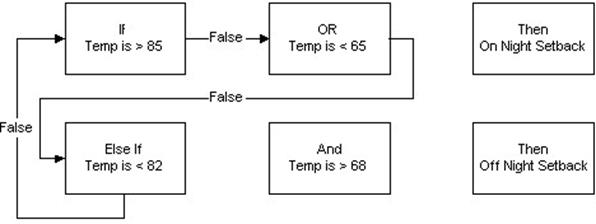

Program Logic Sequence: Use English-language, If / Then statements to customize the sequence of operations.

Points can be configured as Binary Outputs, Binary Inputs, Analog Outputs, or Analog Inputs. The point in the example is a Software Binary Output. The buttons listed below are found only on certain point types.

Software/Hardware: Indicates whether points are software or hardware. Hardware points are physically wired to the controller. Software points include information that affects the functioning of hardware points. Clicking this button tells you where a point is physically located and how it is configured.

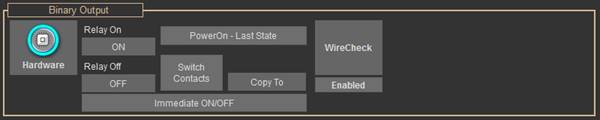

Relay On/Relay Off: Allows you to view and change the units of measurement for the point. Click the button with the existing unit of measurement. A window with a list of measurement options from which to select will appear. The buttons will look different for various point types. These buttons are found on Binary Outputs only.

Switch Contacts: For Binary points, you can reverse the relationship between the position of the dry contact (relay) and the status of the point you are controlling. For example, a relay is normally wired to turn an AHU on when the relay is commanded on. If instead, the relay is wired in a way that the AHU turns off when the relay is commanded on, you can click this button to inform CBAS that the relationship is reversed. Found only on Binary Output points.

Copy To: Copies all the Programming and parameters from this point to another point of the same type. Click the button and you will see a list of similar points in the database.

Immediate ON/OFF: Allows you to delay the starting and stopping of equipment in order to spread out the energy consumption. Applies to Binary Output points on a controller only. Not system wide.

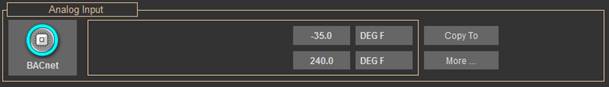

More: Gives you more options based on the properties of the point so that you can customize the properties of the point. Only found on Analog Input points. From here you can add an offset to the status of a sensor if you believe it is inaccurate. Starting in CBAS 15, there is a field to insert the number of Decimal places in the value of the input.

DEG F: Allows you to change the units of measurement and the parameters of the point. Found on Analog points.

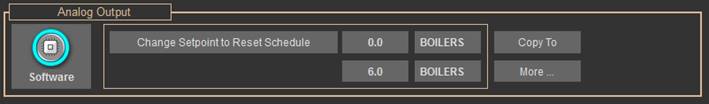

Change Set point to Reset Schedule: Allows you to change a Setpoint to a Reset Schedule, and vice versa.

Recording and viewing Histories lets the user know how the status of a point has changed over time. By knowing what has happened in the past, you can better understand what will happen in the future, and set baselines to know when the equipment is functioning properly. Troubleshooting is more manageable with a good understanding of how points have reacted to past changes in the environment.

To begin Recording History:

· From the Point Program Screen, click the History button to view histories or set the parameters for saving Histories.

· Begin saving new data by enabling the history. This can be done by clicking the Disabled button under the History button in the Point Program Screen or by clicking the History button, then checking the History Enabled box in the Point History screen. To disable history, uncheck the History Enabled box.

· To change History Saving parameters, click the History Button, then click the “Modify History Saving Settings for this Point” button.

For Binary points, all changes of state are saved. For analog points, history is recorded based on parameters set by the user. In the History Settings screen, you can define how often data is recorded. Both of the conditions below must be met in order for data to be saved to the history file.

Minimum Report Time: Sets the least amount of time that must pass before data is saved to the History file. Click 00:15:00, and then use the arrows to make adjustments. In the example above, 15 minutes must elapse before a temperature is recorded. This is the default, but can be lowered for a more detailed History Graph on some points.

Minimum Analog Counts: Sets the minimum change in status that must occur before history is recorded. Click 3.0 DEG F, then, type in your desired minimum change. In the example on the previous page, temperature must change by 3 Deg F before a point in time is recorded.

In the above example, the temperature must change by 3 Deg F within 15, 30, 45, etc. minutes for a history save to occur. To get the most realistic looking graph, lower these settings to 1 minute and .1 degree. Do this only on points that you need to keep an accurate history of. Otherwise, the History file will become bloated with unneeded data, which could lead to problems. Also, histories need to be purged of old data regularly. This can be done through the History Maintenance function on the System Menu. System Menu items are discussed in detail in Chapter 5. As of CBAS 15.2, purging of history is done automatically and all purged files are accessed when necessary. So manual purging is no longer necessary.

![]()

To graph a Point History:

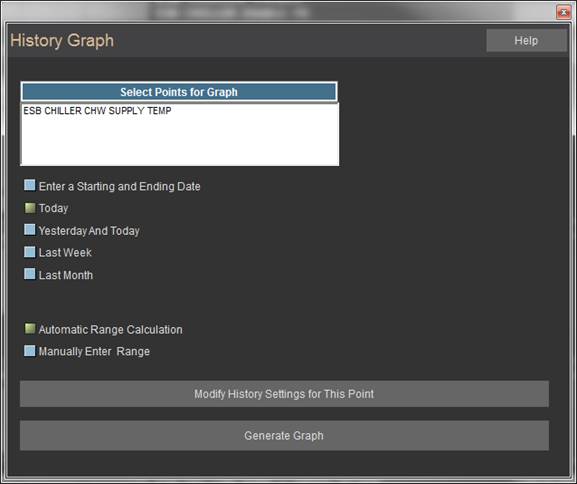

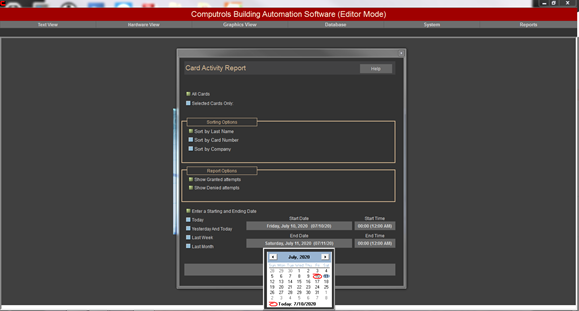

· From the Point History screen, click to display a graphical representation of a point’s history. The window below will appear:

· In order to make comparisons, up to 4 points can be chosen to graph at the same time. For example, you can see when a fan started by choosing the Start/ Stop point, and see how the supply air and space temperatures change as a result, by choosing those points for the same graph. Click “Select Points for Graph”, choose your points from the list, and then right click.

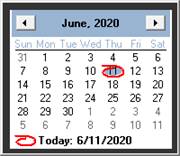

· Choose a time period for the graph by checking one of the boxes on the left. Above is an example with Enter a Starting and Ending Date checked. Click on the Starting or Ending Date and a calendar will appear.

· To change the Month, click the month and choose from the list. To change the year, click it then the up and down arrows. Or, you can use the left and right arrows to change the month and year.

· Today’s date will be circled in Red. Right-click anywhere on the calendar to select today’s date, or click on another date to choose it.

· Click on the Start or End Time to change. Move the time forward and backward by clicking the up and down arrows next to the time.

· Click the Display Graph button to open a History Graph. The resulting graph displays the history for the points and time frame selected in step 2.

The points are listed at the top of the screen and are color coded to match the units of measurement on the left side of the graph (Y-axis). Across the bottom (X-axis) are the dates. Each point has a unique colored line to represent the change in its value over time. When you move the cursor, you will notice lines pointing to the X- and Y-axis, where the date and value are displayed.

Zoom In: Allows you to closely view a section of the graph. Click a location on the graph as the starting point and then click an ending point. The space between the two points will be displayed when you zoom in.

Zoom Out: Displays the graph from which you zoomed in.

Print: Sends the displayed graph to the printer.

Let’s say that you have a point that is being commanded by LOG1, but there is no logic programmed on that point. Go to Point Relations and you will find what is commanding the point.

The Point Relations window shows you what other points are related to this point by way of Logic Statements, PIDs, Alarms, etc. There is no configuration necessary. However, if you click on a line, CBAS will show you the Logic Statement, Schedule, etc. that references the point name.

Here is an example of the Point Relations Screen:

Another feature of Point Relations is the *, which denotes items residing in the “Child Panel.” First of all, any controller programmed in CBAS is a Child Panel. In addition to the Parent Database that you see in CBAS, there is a Child Database that is downloaded to the controller whenever changes are made. The Child Database is kept separate in order to facilitate the download to the correct address.

Usually, Logic is programmed on a Point which resides on a Controller (Child Panel). But sometimes Logic may be programmed on a point that resides on the head-end (Server). If the * is not present, the point resides on the head-end by choice, or the Logic has not yet downloaded to the Child Controller (Database Scaling may be necessary). If a logic contains points on more than one controller, the logic will remain on the head-end.

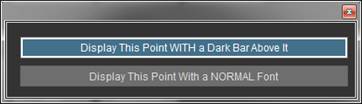

In this feature, there are some other tools for organizing and grouping points in Text View. When you click on the Display Options button, the following box appears:

· Click once on the top button to add a dark bar above the point. Click once more to remove it

· Click once on the bottom button to change the name to a bold font. Click once more to change it back to a normal font.

These options can also be changed in Text View by using the following function keys:

F3: In Text View, you can add bold lines between points by highlighting a point and pressing the F3 function key. This will add a bold line above the point. Press F3 again to remove the line. This feature is good for creating groupings of related points.

F4: Also, you can bold the name of a particular point by highlighting it and pressing F4. Press F4 again to return to normal font.

This menu item allows the user to change the position of the point in Text View, so points that need to be viewed more often can be placed at the top of the list and associated points can be grouped together. When you click this button, the following window appears:

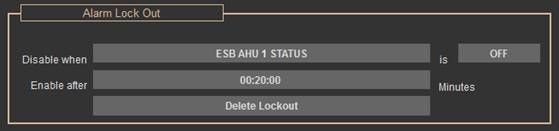

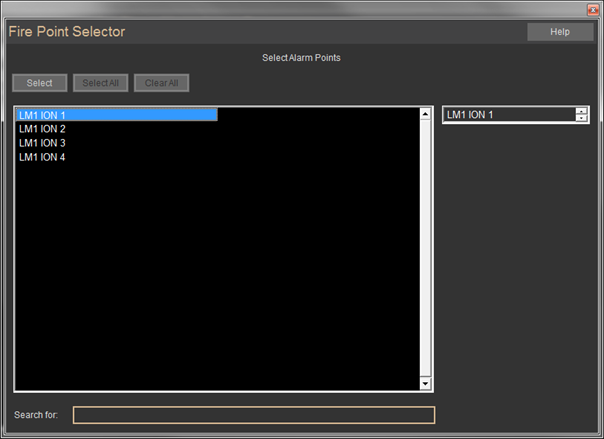

The point you are repositioning will have a green background. Place your mouse pointer where you want the point moved to and a red line will appear. Click there and the point will be moved. If you have a hard time finding the location, you can search by typing the name or part of the name and hitting the + or – signs on the 10 key pad of your keyboard. Multiple points can be positioned at the same time by going to Position Points on the System Menu.