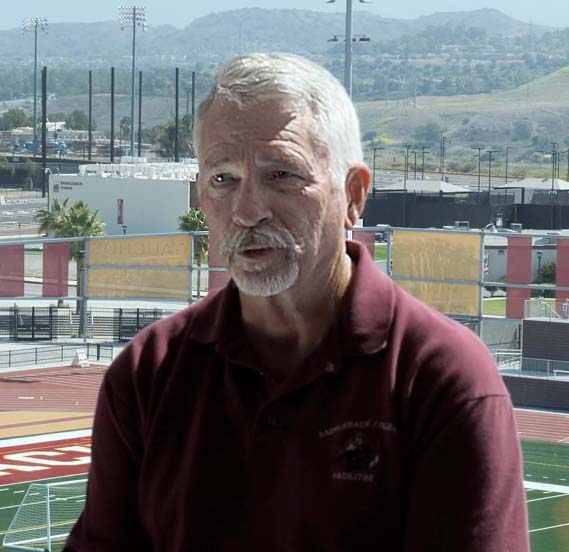

Alan Cherry

Plant Engineer at Saddleback College

Plant Engineer

The combination of the system and the support Computrols provides is just great. The software is so easy to use, it’s allowed us to identify a lot of different ways to save energy on our campus.