Don Gaspard is both a long-time Computrols customer and experienced facility manager. Mr. Gaspard is a military veteran who initially entered into the field of HVAC and refrigeration after attending Delgado Community College. After spending several years as an Air-conditioning Technician, he began his career in facility management at a New Orleans-based healthcare facility. For a number of years Don worked at numerous facilities in both hospitality & healthcare. He then started in his current role as the Director of Facilities at Touro Infirmary where he has spent the past 14 years.

Don Gaspard is both a long-time Computrols customer and experienced facility manager. Mr. Gaspard is a military veteran who initially entered into the field of HVAC and refrigeration after attending Delgado Community College. After spending several years as an Air-conditioning Technician, he began his career in facility management at a New Orleans-based healthcare facility. For a number of years Don worked at numerous facilities in both hospitality & healthcare. He then started in his current role as the Director of Facilities at Touro Infirmary where he has spent the past 14 years.

What makes operating a healthcare facility different from operating any other kind of facility?

In a word, compliance. As healthcare facility managers, we are required to maintain the standards set forth by the Joint Commission, CMS (Centers for Medicare & Medicaid Services), Fire Marshal, and DHH (Department of Health & Hospitals) 24/7/365.

Along with maintaining these standards, detailed documentation must also be kept verifying that testing and inspections are being executed per the requirements. Regular training must also be conducted for both the facilities team and other departments in the hospital to ensure they understand both life safety and infection control standards as they affect their work area, for the protection of our patients.

Why are building automation systems especially important to healthcare facilities?

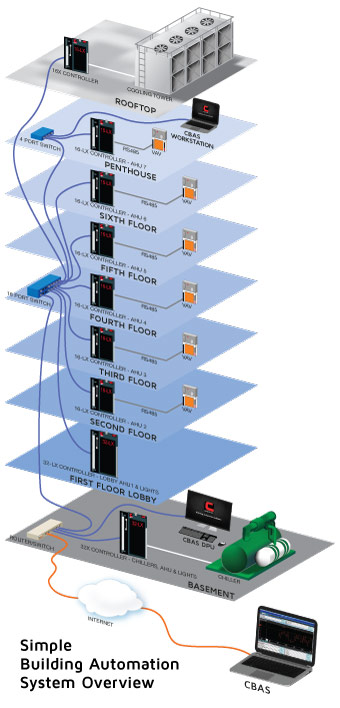

Well, I think they have really made their mark not just in healthcare facilities, but in many other industries as well. To get a real appreciation for building automation systems, you have to understand that 30+ years ago an operating engineer or “watch engineer” as they were known back then were required to stay in the engine room to continually watch pressure & temperature gauges & instruments that required frequent adjustments to keep the equipment working properly.

Well, I think they have really made their mark not just in healthcare facilities, but in many other industries as well. To get a real appreciation for building automation systems, you have to understand that 30+ years ago an operating engineer or “watch engineer” as they were known back then were required to stay in the engine room to continually watch pressure & temperature gauges & instruments that required frequent adjustments to keep the equipment working properly.

In today’s world where everyone is being asked to do more with less personnel, automation systems are better controlling & maintaining the designed conditions of the plant without constant monitoring. This allows the Plant Engineer to be more productive and not restricted to the central plant for their entire shift. Today’s automation systems allow the operators to set control parameters and alarm settings that can notify the operator via text or e-mail whenever equipment requires attention. In critical areas such as operating rooms or other patient care areas, the system can also notify the nursing staff if required conditions are not being maintained.

In addition to comfort and security, has sustainability become an expectation in the healthcare industry as well?

Well yes definitely. There is a lot of pressure to become more “green” and reduce energy consumption in hospitals. It’s really an uphill battle since even though we purchase more energy efficient equipment and make control adjustments to reduce energy usage, utility costs continue to increase, offsetting a portion of the gains we have made.

In hospitals, there are limitations to the adjustments that can be made to the environmental controls, because in a lot of areas, there are specific temperature, humidity, and pressure requirements to be maintained.

What about Computrols products make them a particularly good fit for healthcare facilities?

I think the Computrols system is more user-friendly than any other system that I have used over the years. I have used Johnson Controls, Siemens, Honeywell and a few smaller vendors systems, and to me, Computrols is the most intuitive. The software is the easiest one to learn and go in and make changes to programming. A big reason for this is because it uses regular English language rather than code when writing programming sequences. That’s one advantage that I see with Computrols.

One of the reasons we chose Computrols is because they could integrate with the Siemens system we had and use most of their existing controllers, rather than having to replace the entire system at the start. As we renovate, we are converting to a pure Computrols system but at the time of the change, this method was less disruptive than changing out the entire old Siemens system.

Working with Computrols over the past decade has truly been a partnership. From their sales team to their technicians, they always have their customers’ best interests at heart. I can’t think of another service partner over my career that provided such a high level of customer service with a product to match. They believe facility managers should be able to run their own BAS, and everything that they do as a company supports that belief.